Achieving goals requires having mechanisms for managing inventories effectively. Systems for compelling inventory are essential to businesses. According to a Harvard Business Review research, businesses with effective inventory management are 20% more successful. This examines those who are devoid of it. Significant financial losses might also result from ineffective inventory management systems. Unorganized inventory management cost custom software development outsourcing organizations, on average, 25% of their annual revenue. This was reported by the National Retail Federation. Furthermore, inventory control is essential. It’s essential to maintaining and satisfying customers. According to a study by Bain & Company, 65% of consumers are not likely to shop at the same store again.

Systems for managing inventories are essential for competence. This is something that logistics inventory management does in addition to helping with money and clients. The Aberdeen Group found that the best companies in inventory management achieve 95% accuracy. They likewise accomplish 89% request satisfaction rates. They can reduce stockouts and excess inventory, as well as streamline lifecycles. This lowers costs and boosts efficiency. These guidelines and procedures apply to all parties. This increases efficiency and reduces expenses. These standards and practices are for everybody. Inventory management in supply chain will act as a guide for entrepreneurs and supply chain experts.

Understanding the Basics of Inventory Management Systems

Whether you’re new to the field or refreshing your knowledge, you must grasp the fundamentals of inventory systems.

1. Definition of Inventory Management Systems

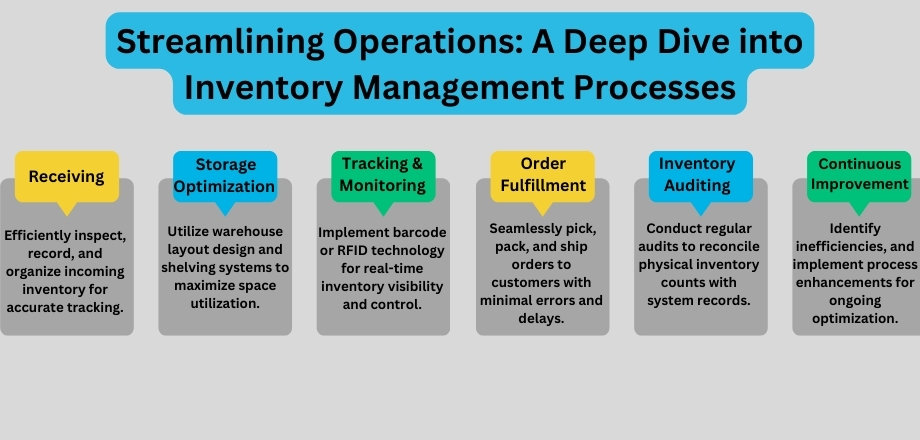

Inventory management systems allude to the cycles and innovations used to supervise the progression of products and materials in a business. These systems envelop various exercises, including procurement, storage, tracking, and fulfillment, aimed at maintaining ideal inventory levels to satisfy customer needs while minimizing costs.

2. Importance of Effective Inventory Management

Effective inventory management is indispensable to the outcome of any business, paying little heed to estimate or industry. Custom software development consulting companies with compelling inventory management systems experience higher benefits. For instance, according to a report by McKinsey & Company, companies with optimal inventory management practices can reduce their working capital requirements by up to 30%. Additionally, maintaining precise inventory records and minimizing stockouts can upgrade customer fulfillment, prompting expanded deals and income.

3. Challenges in Traditional Inventory Management

Customary inventory management techniques, like manual tracking or bookkeeping sheets, are inclined to blunders and shortcomings. Research conducted by the International Data Corporation (IDC) reveals that businesses lose approximately $1.3 trillion globally each year due to software testing life cycle-related issues, including overstocking, stockouts, and shrinkage. Without appropriate systems set up, businesses might battle to gauge demand, bringing about overabundance inventory or deficiencies.

4. The Role of Inventory Management Systems in Business Operations

Inventory management systems automate and streamline inventory-related processes, further developing exactness and proficiency. High level elements, for example, demand determining calculations and continuous tracking, empower businesses to optimize inventory levels, diminish conveying costs, and answer changes in demand. Moreover, reconciliation with other business systems, for example, bookkeeping and supply chain management software, works with seamless coordination across divisions, upgrading functional viability.

In the later segments, we will dig further into every part of inventory management systems, giving useful bits of knowledge and methodologies to assist you with improving your inventory control cycles and drive sustainable development. Whether you’re aiming to diminish abundance inventory, further develop request fulfillment rates, or improve customer fulfillment, dominating the fundamentals of inventory management systems is the most important move towards accomplishing your business objectives.

How Do You Select the Right Inventory Management System for Your Business?

Picking the right inventory management system is a basic choice for any business. With a huge number of choices available on the lookout, choosing the framework that lines up with your one of a kind necessities and goals can influence your functional effectiveness and primary concern. In this -guide, we will investigate the critical elements to consider while assessing inventory management systems and give significant experiences to assist you with pursuing an educated choice.

1. Assess Your Business Needs

Prior to setting out on the determination interaction, checking your business requirements is vital. Consider factors, for example, the size of your inventory, the intricacy of your supply chain, and your development projections. Directing careful requirements evaluation will assist you with distinguishing the particular elements and functionalities fundamental for your software development outsourcing organization’s operations.

2. Scalability and Flexibility

As your business develops and advances, your inventory management necessities will change. Select a framework that offers versatility and adaptability to oblige future development and adjust to developing business prerequisites. As per a review by Aberdeen Gathering, 46% of businesses refer to versatility as a basic figure choosing an inventory management arrangement.

3. Integration Capabilities

Seamless integration with existing software systems is imperative for boosting operational efficiency and information precision. Search for inventory management systems that offer robust integration capabilities with other business applications, like accounting, e-commerce platforms, and ERP systems. Research indicates that logistics inventory management that integrates their inventory management systems with other software solutions experiences huge efficiency gains and cost investment funds.

4. Cost and ROI Analysis

Cost is significant. However, you must check the return on investment (ROI) of using an inventory system. Consider the forthright costs. These include licensing and implementation fees. Likewise, consider the continuous costs of maintenance and backing. Inventory management in supply chain can save investment budgets and time. This happens through better inventory management, lower conveying costs, and higher efficiency.

5. Interface and Training Support

Great interfaces and intensive training are pivotal. They ensure the reception and use of the inventory system. This will minimize the learning curve for your team. Likewise, consider the availability of training resources. These include online instructional exercises and customer support services. They help with smooth implementation and progressing use.

Transform Your Software Vision into Reality – Book A 30 Minutes Free Consultation!

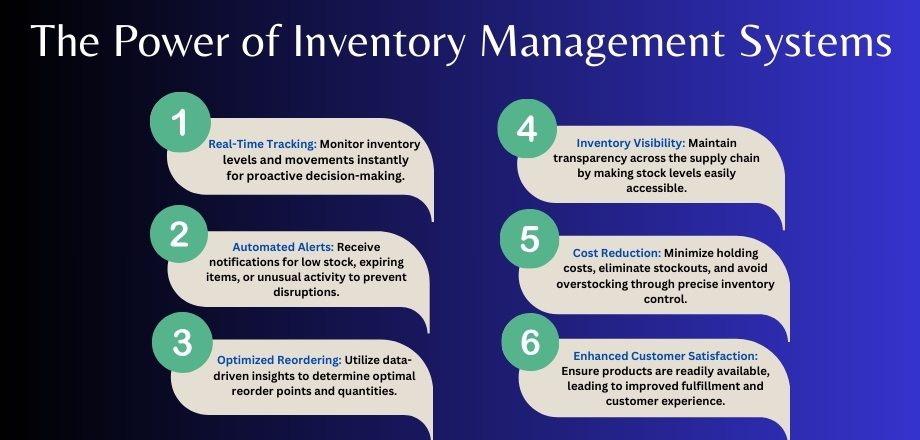

Essential Key Features and Functionality of Modern Inventory Management Systems

Inventory management software helps you cut inventory holding costs. Great inventory control features are key to a smooth process. Wondering how you can tell what features your inventory system needs?

We recommend these 10 features. We based this on their prevalence and importance for most businesses. We’ll analyze their benefits so you can answer the question yourself. Likewise, we’ll provide a checklist of the system requirements for each feature. Supply chain inventory management will have technical keywords. This will help you track down more references. It will likewise help you reach reputable software providers.

1. Centralized Inventory Management

An inventory management system has a key feature. It can centralize immeasurably significant inventory information. It offers full oversight of stock levels, item histories, and item details. This centralization is key. It ensures that inventory data adjusts across many channels and departments. This lifts exactness and eases operations. Centralized systems empower teams. They can collaborate well, regardless of where they are. This ensures that everyone approaches the same, current inventory information. Multi-Source Inventory (MSI) shows the benefits of robotizing stock management across many warehouses. It makes overseeing stock faster and more precise.

2. Tagging and Barcoding

Labeling and barcoding are fundamental features for minimizing human error in inventory management. These technologies speed up information entry. They likewise cut the time and resources spent on staff training and information recording. Barcoding speeds up undertakings that once required long stretches of difficult work. Inventory Management Systems slices the time to a small portion. It supports efficiency and cuts the chances of costly mistakes. Inventory systems enable the precise tracking of items. They do this through labeling and barcoding. They track each item’s excursion from the warehouse to the customer.

3. Reporting of Business Activities

Generating detailed reports is a key capability of an inventory system. It is very valuable. Real-time reporting tools give managers and stakeholders. This includes the area of drivers. It additionally includes the stock status and shipment progress. This feature ensures that decision-makers are well-informed. They can respond to changing market demands, logistics issues, or inventory problems. You can integrate advanced reporting capabilities into an inventory system. This makes it a powerful instrument for strategic preparation and oversight.

4. Forecasting of The Inventory

It lets custom software development consulting companies predict demand and manage supply well. An inventory system with solid forecasting can track down trends. It can alert companies to items that are selling quickly. We can likewise advise them about items that have excessive stock. This prediction capacity helps keep customers cheerful by staying away from stockouts. It likewise optimized resource allotment, enabling smarter buying. The system uses verifiable information. It helps managers coordinate inventory levels with customer demand. This reduces the gamble of excess stock.

5. Alerts Regarding Inventory Details

Modern inventory systems support efficiency. They do this with automated alerts. The alerts tell managers about the low stock. These warnings help stop issues. For example, run short on a popular item. They alert the responsible parties before it becomes a problem. Software testing life cycle proactive features save time and resources. Otherwise, they would spend the time on manual stock supervision. It ensures that inventory management is both responsive and strategic.

6. Backup and Security of The Inventory

Keeping inventory information accurate is important. The systems have solid security. It protects against unauthorized access and cyber threats. In addition to solid security conventions, these systems have reinforcements to prevent information misfortune. On the off chance that a breach happens, the reinforcement keeps operations going. This two-section way to deal with information protection is essential. It keeps the system reliable and maintains users’ trust.

7. Internet of Things (IoT) and Cloud Data Software

IoT is integrating with cloud-based inventory systems. This integration is changing the tracking and management of inventory. This technology takes into account real-time information collection and examination. It works across a wide range of devices. It makes inventory management more unique and responsive. IoT devices can record and update inventory levels. Inventory Management Systems give employees immediate access to current information. These systems are cloud-based, so users can access the information. Software development outsourcing services ensure that all team members have the most modern information. It helps them make better decisions and optimize inventory.

8. Integration with Other Systems

It is a major advantage to connect inventory management software with other systems. These include Enterprise Resource Planning (ERP). Seamless integration permits information to stream without interruption. It improves the capability of the two systems. These include finance, customer management, and the supply chain. This leads to improved precision and a better view of the organization’s performance.

9. Optimized Inventory

Inventory enhancement is a key feature of sophisticated inventory management systems. These systems use calculations and investigation. Managers can operate better and meet deadlines by setting inventory levels to meet current needs. This helps make operations smoother and save money.

Best Practices for Implementing and Integrating Inventory Management Systems

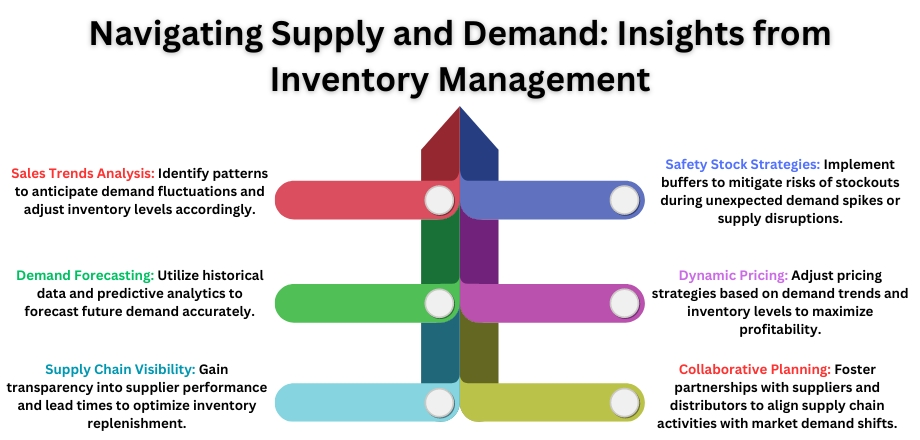

Flourishing organizations face extreme competition. They ought to realize that inventory management is key. Custom software development companies in USA must balance supply and demand to ensure enough stock is generally available to meet customer needs. Here are seven inventory management best practices that can help organizations keep steady over stock levels and maximize availability.

1. Create a Forecasting Model

Great inventory management is tied in with understanding consumer demand. It’s tied in with ensuring enough supply is available to meet those needs. Forecasting instruments can help users maintain healthy stock levels. The devices can analyze many pieces of consumer demand. They include authentic trends, advancements, and market position. They use this data to predict the best quantity of each product.

2. Build Realistic Lead Times

Lead time is how much time between ordering an item from a manufacturer and making it available to a customer. The process begins when a customer orders an item through an order management system. Lead times depend on many variables. These include the time for making things. Likewise, the time to move them to a warehouse. Furthermore, if necessary, the time for international travel. Ascertaining realistic lead times is significant for some aspects of operations. For example, customers will likely be irate assuming their order takes longer to arrive than predicted.

03. Minimize Unused Capital

Holding inventory has many costs. Expenses come from processes like purchasing unrefined substances, making items, and conveying them. These costs can hurt overall revenues. Companies must cut how much capital tied up in sluggish inventory to free up income. Doing so requires a delicate balance between supply, demand, and stock. Using a just-in-time fabricating model can cut lead times.

4. Optimize Warehouse Operations

Warehouse optimization can make a major difference in the safe storage of items and the speedy fulfillment of orders. Employees ought to store items in a controlled and secure environment to keep away from damage or theft. After storage, employees must complete regular inventory builds up to identify any discrepancies. Warehouse employees can likewise place items that won’t be in that frame of mind for quite a while in easily accessible areas inside the warehouse.

Automation, advanced mechanics, and comparative technology can likewise help optimize warehouse operations. Conveyor systems for moving items and putting them away in item receptacles and robots that pick and pack orders can make inventory management easier to do for the software testing life cycle.

5. Integrate technologies

Inventory management relies on the integration of multiple systems and processes. Perceivability into every piece of the supply chain helps ensure efficient creation, transport, and fulfillment of inventory. An organization’s ERP system can provide knowledge into finances, staffing requirements, and operational needs.

Many warehouse management systems (WMSes) can handle inventory errands, yet on the off chance that it does not, integrating an Inventory Management System (IMS) in an organization’s existing WMS can help. Using a transportation management system alongside a WMS can give understanding into item appearance times.

Integrating with other supply chain stakeholders and outsiders’ technology is crucial also. Hospital inventory management software is able to send data between their organization’s IMS and, for example, another organization’s assembling stage.

6. Regularly Count Inventory

Multiple issues, including incorrect storage, misspeaks, and theft, can cause discrepancies between an IMS’s warehouse information and the number of items that are really stored at a warehouse. Counting inventory can help get these issues early and help employees address the cause of the problem.

One effective inventory counting strategy is a cycle counting approach. This method categorizes items as per demand, prices, and other variables to create a need list that indicates the frequency with which employees ought to count each product offering. Software development outsourcing companies count the highest need items first, dropping down the rundown of priorities on a case by case basis.

7. Plan for Peak Season

Numerous industries experience a peak season, resulting in higher demand for certain items. For example, the peak season for consumer products tends to happen between mid-November and late December in the U.S. and Europe because of the Christmas season.

Companies must prepare for their industry’s peak season. Some strategies include ensuring adequate employees will be working at that time, tightening lead times, and integrating the peak season into demand forecasts.

Unlock Your Business Potential with Custom Software Solutions. Contact us Today!

How do You Optimize Inventory Management Systems for Increased Efficiency and Profitability?

As we delve deeper into the transformative potential of artificial intelligence in software development in the business realm, let’s explore the 11 different ways AI supports Efficiency and Productivity in Inventory Management.

1. Predictive Analytics for Demand Forecasting

Predictive analytics uses verifiable information. Inventory Management Systems uses factual algorithms and machine learning. They are used to predict future outcomes. It identifies patterns and trends from past information and predicts the likelihood of future occurrences. Demand forecasting is different. It is the process of estimating the amount of an item or service consumers will purchase from now on. Inventory management in supply chain uses information and analytics to predict what consumer demand will be during a specific period.

2. Improved Stock Replenishment with AI

Stock replenishment is a basic process in inventory management, ensuring that items are consistently available to meet customer demand. Customary stock replenishment methods often rely on manual processes and human judgment, leading to several issues:

- Overstocking: Without accurate demand forecasting, custom software development consulting companies often overstock products ‘in case.’ This leads to high carrying costs and an increased risk of wastage or obsolescence.

- Understocking: Conversely, underestimating demand can lead to understocking, resulting in stockouts, lost sales, and a poor customer experience.

- Time and Effort: Manual stock replenishment is time-consuming and labor-intensive, reducing operational efficiency.

3. Real-time inventory monitoring and control through AI

The capacity to watch and control inventory in real-time is a game-changer in the present business landscape. It enables effective inventory management as well as lifts operational efficiency and customer fulfillment.

- Prompt Decision Making: Real-time inventory information allows businesses to make immediate and informed decisions. This might involve adjusting orders, shifting resources, or launching unexpected promotions to move surplus stock.

- Prevention of Stockouts and Overstocking: Real-time inventory management facilitates optimal inventory levels. This prevents both stockouts, which can lead to lost sales and dissatisfied customers, and overstocking, which can result in higher holding costs and waste.

- Enhanced Customer Service: By providing accurate and real-time information about product availability and expected delivery times, Inventory Management Systems help businesses significantly enhance their customer service experience.

4. Enhanced supply chain visibility with AI

Supply chain perceivability refers to the capacity to follow each component or item from the manufacturer to the end consumer. It involves the transparency of movements of every kind related to supply chain processes — procurement, producing, logistics, warehousing, and sales.

- Risk Management: Enhanced visibility helps businesses identify potential risks and disruptions in the supply chain before they escalate, thus enabling timely corrective action.

- Improved Efficiency: It facilitates coordination and collaboration across different stages of the supply chain, thereby increasing operational efficiency.

- Customer Satisfaction: By providing accurate information about product availability and delivery times, supply chain visibility enhances the customer experience.

5. AI-driven automated purchasing: A game-changer

Automated buying refers to the use of technology to streamline and automate the procurement process. It involves the automatic generation of purchase orders based on predetermined triggers, for example, inventory reaching reorder focuses.

- Efficiency: Automating the procurement process reduces manual labor, speeds up the purchasing cycle, and minimizes human error.

- Cost Reduction: It helps avoid situations of overstocking and understocking, leading to cost savings related to inventory management.

- Control: Automated purchasing systems provide better control over the purchasing process and enhance supplier management.

6. Intelligent warehouse management enabled by AI

Warehouse management is at the core of any supply chain operation. Proper Custom software development companies in USA storage and movement of products inside a warehouse directly influence the overall business efficiency.

- Operational Efficiency: Effective Custom software development companies in USA and management of inventory reduce handling costs and improve the speed of the in-and-out movement of goods.

- Optimized Storage: Proper warehouse management ensures the best use of available space, leading to reduced storage costs and increased capacity.

- Customer Satisfaction: A well-managed warehouse ensures timely and accurate order fulfilment, which directly enhances the customer experience and loyalty.

7. Efficient order management and fulfillment through AI

Order management and fulfillment structure the essence of any business operation, connecting customer orders to inventory management, item delivery, and after-sales service.

- Customer Experience: Efficient order processing and fulfillment enhance customer satisfaction by ensuring timely and accurate delivery of products or services.

- Inventory Turnover: Effective order management is crucial for optimizing inventory levels and reducing storage costs for the software testing life cycle.

- Revenue Realization: Proper fulfillment ensures that orders translate into revenue without delays or discrepancies.

8. Waste reduction through smart inventory disposal with AI

Waste in inventory management is an age-old problem. However, in the present era of sustainability and cost-efficiency, it has become even more pressing. Moreover, excess stock that becomes obsolete, perishables that decay, and sluggish items that consume valuable space all contribute to inefficiencies in inventory management. The consequences are costly and terrible.

- Overstocking: Holding excessive stock can lead to obsolescence, especially for products with a limited shelf life. This not only ties up capital but also results in waste products that have to be discarded.

- Understocking: On the flip side, understocking leads to missed sales opportunities but also results in rushed purchasing decisions that might not always be economically or environmentally friendly.

- Inaccurate Forecasting: Misjudging demand can result in both overstocking and understocking, each leading to its own set of waste.

- Space Utilization: Slow-moving or obsolete items can consume valuable warehouse space, leading to increased storage costs and reduced efficiency.

9. Minimization of human errors with AI in inventory management

Inventory management is complex and, when done physically or with limited technological aid, prone to errors.

- Data Entry Mistakes: Simple keystroke errors or misreadings can lead to discrepancies in inventory records.

- Misjudgment in Forecasting: Humans, relying on gut feelings or insufficient data, might misjudge demand, leading to overstocking or stockouts for the agile software development life cycle.

- Handling Errors: Physical mishandling of goods, misplacement, or overlooking items during stock counts are common human-induced errors.

10. Enhanced customer satisfaction through optimal inventory levels with AI

Custom software development services USA inventory levels directly correlate with its capacity to meet customer demands. Getting this balance right assumes an essential part in molding customer perceptions and experiences.

- Product Availability: Nothing dampens a customer’s experience quite like finding their desired product out of stock. On the other hand, always-available products enhance trust and reliability perceptions.

- Timely Deliveries: Adequate stock levels ensure that there are no unnecessary delays in product dispatch and delivery. Timely deliveries in logistics inventory management are often a crucial determinant of customer satisfaction.

- Variety and Choice: Maintaining optimal levels of a broad inventory range means customers have more choices, which can enhance the shopping experience.

11. Advanced reporting and analytics for improved decision-making with AI

In the intricate universe of inventory management, understanding past performance, current status, and future trends is vital. This understanding hinges on robust reporting and analytics.

- Performance Review: Without metrics and reports, it’s challenging to gauge if inventory processes are effective or if there’s room for improvement.

- Operational Oversight: Detailed analytics offer insights into every facet of the inventory, from stock levels and turnover rates to warehousing costs and supply chain efficiency.

- Forecasting: Accurate predictions for future demand, seasonal variations, and market shifts can be the difference between profitability and loss.

- Risk Management: Data-driven insights can highlight vulnerabilities in the supply chain or potential stockout scenarios, allowing software development outsourcing companies to act proactively.

Transform Your Business with Custom Software Development. Request a Free Consultation Today!

Overcoming Common Challenges in Using Inventory Management Systems

While there are numerous problems faced in inventory management, here are the top challenges and solutions to overcome them.

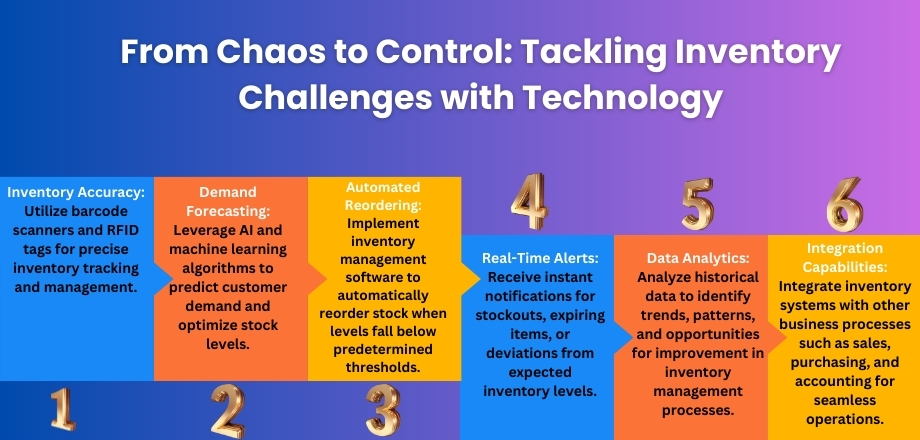

1. Lack of real-time Inventory Visibility

This is one of the biggest challenges in inventory management. As a business, you need to know the real-time status of stocks in your inventory. Regardless of where the products are, you must keep a keen track of them. Awful inventory checking causes late transportation. It likewise causes extra transportation costs and unbalanced inventory.

How can you solve it?

Real-time Inventory Management System: This tells you exactly where your products are. Additionally, it will likewise give you a closer understanding into the availability of stocks at that moment.

2. Overstocking and Understocking

Overstocking happens when a business holds excessive inventory, tying up valuable capital and storage space. At the same time, understocking happens when inventory management systems levels are insufficient to meet customer demand. Research shows that reducing stockouts and overstocks can lower inventory costs by 10%.

How can you solve it?

Effective Demand Forecasting: The key to handling overstocking and understocking is leveraging sophisticated analytics and reporting dashboards that can help you gain a better understanding of your information and keep track of impending events while checking the needed inventory levels for the future.

3. Redundant Manual Procedures

Tracking your inventory with essential manual procedures can lead to errors in overseeing merchandise. Likewise, manual picking, pressing, and transportation processes can dial back order fulfillment, which can lead to delayed delivery and hamper customer fulfillment.

How can you solve it?

Invest in Cutting-edge Technology Solutions: To address this challenge, software development outsourcing companies ought to invest in modern technology solutions like inventory management, warehouse management, and multichannel order management. Mechanizing the procedures will make it easier to track and report on the availability of the products.

4. Recognizing and Tracking Obsolete Products

It is normal for some items to become obsolete after their demand drops. People often leave these old products in warehouses. They forget about them when they need them. At such times, inventory managers might end up ordering new items that leave the old stock unused, resulting in a misfortune.

How can you solve it?

Stock Control Systems: This system is useful in hunting dead inventory and using it when required. Expiry management and stock revolution methods are examples of FIFO and FEFO. They make sure that older inventory is used before newer stock. Inventory management in supply chain prevents accumulating. It ensures that items are used in the order they were received.

5. Understanding Demand and Volatility

E-commerce businesses must understand demand and instability. These things are essential in the present quick evolving markets. Demand for products can be uncertain. It depends on factors like season, area, and market trends. Additionally, market trends likewise fluctuate. This can lead to a shortage of merchandise when demand rises or excess stock when demand is low.

How can you solve it?

The software has comprehensive reports and a dashboard. They can help you analyze real-time information. This will enable businesses to predict demand and enhance their forecasting precision. Approaching current and accurate information empowers businesses. It lets them make informed choices and adjust their operations to meet evolving demand.

6. Lack of Integration with Sales Channels

The present retail is omnichannel. Businesses often sell items through various sales channels. These include online stores, actual stores, marketplaces, and virtual entertainment. Each channel might have its inventory system. Supply chain inventory management can cause discrepancies and inconsistent updates across them. For example, in the event that an item sells out on one stage however the inventory isn’t updated on another, there’s a gamble of overselling. This can lead to canceled orders and troubled customers.

How can you solve it?

Centralized Inventory Management Systems: Set up a system that synchronizes inventory levels in real-time. It will work across all sales channels. This makes sure that inventory information is accurate and forward-thinking. It cuts the gamble of overselling and helps meet customer demand better.

7. Handling Perishable and Fragile Stock

Some items need special care. This includes perishable products, like fresh produce and dairy. The agile software development life cycle additionally includes fragile items like glassware and electronics. This is true both during storage and travel. It’s vital to follow their circumstances and use them before they expire or become damaged.

How can you solve it?

To manage perishable and fragile stock, custom software development consulting companies ought to use a system to manage expiration. This involves clear item labels and arranging. Furthermore, adhering to the earliest in, earliest out approach entails real-time observing of storage conditions. Additionally, it encompasses automated alerts and the integration of stock perceivability inside the inventory system.

How do you integrate inventory management systems with Other Business Tools and Software?

Inventory management continues to play a critical role in the success of Custom software development companies in USA. However, because of the domino effect businesses have on the economy, recently “unsold inventory created a big drag on the economy.” According to NRF Chief Executive Matthew Shay, inventory challenges contributed to the unmet sales goals of the recent holiday season.

Excess inventory is bad. But product shortages are as bad. Out-of-stock inventory troubles both the business and the customer. Finding balance then becomes pivotal to the success of a business. In a recent study by the Aberdeen Group, top businesses were able to “rightsize” their inventory. They did this by assessing items, down to the SKU level. Inventory systems are a great method for seeing item information. They include details about each SKU.

1. Reorder alerts

Reorder alerts, or low inventory alerts, will appear in your inventory system. They tell users when now is the ideal time to reorder an item. The alert will appear when the item level reaches the predetermined reorder level. The system can do this because it can see each item’s sum. This is true even assuming they are in numerous areas. Secure software development framework can likewise see when the item level has become “low.”.

How to use it

You can use inventory information to decide how much buffer stock each item needs. This information includes past sales and expected demand. Then, you can set the reorder alert based on this sum.

Benefit:

- reduction in time spent looking up inventory levels and purchasing.

- reduction in manual efforts to look up inventory levels.

- increased accuracy of inventory levels through automation.

Additionally, inventory software might make purchasing items easier and quicker. For instance, with Acctivate for QuickBooks inventory software, you can create a sale order from the reorder alert. This makes it easy to know when an item level is getting low and easy to reorder that item immediately. Thus, inventory levels are restored. Your business can have better inventory control.

2. Reports

Reports can be created using the report capability in inventory management systems. The information is pulled from the system’s database. Making a report with all the needed information is used. Examples of categories of types of reports and documents available include:

- inventory reports

- sales reports

- purchasing reports

Reports can be standard, meaning they are already available in the inventory management systems. Alternatively, reports can be customized. They are a modified version of a standard report or personalized for a custom software development services USA to show specific information.

How to use it

There are many reports and documents available that can be in every way used in a variety of ways. Depending on the exact inventory management software system, both norm and custom reports might be available. It can create custom reports using its integration with Crystal Reports®.

The reports can be used to determine the greatest inventory sums down to the item level by showing information, for example,

- Inventory analysis by product

- sales history by a specific customer

- Inventory information by lot or serial number for Inventory management in logistics.

- inventory reorder reports that display all products needing to be reordered

Benefit:

The benefit of reporting is that you can see a comprehensive and detailed measure of information at once. This is a time-and effort-saving alternative to looking into every one of the information as well as information. Additionally, reports are an automated approach to collecting information. They have less potential for error.

3. Dashboards

In a software system for inventory management systems, a dashboard is a graphical showcase on the screen. The system’s database holds different information. It very well may be viewed on the dashboard.

How to use it

You can use the dashboard in numerous ways. It shows a wide range of information. Users’ roles in the business determine the way things are used. For instance, a software development outsourcing organization owner could use their dashboard to show month to month sales and inventory per area. However, a warehouse manager could use their dashboard to show the current warehouse inventory. It additionally shows scheduled orders.

Benefit:

Again, like with reports, a dashboard is great. It compiles assorted data and information. The system collects and shows all this data. It saves time and effort and boosts accuracy.

4. Barcoding and Mobile Systems

Barcoding and mobile systems are a blend of hardware and software. They let your business allocate, examine, and manage barcodes. Barcode hardware includes items, for example, barcode scanners and label printers. Barcode software is the system that manages the barcoding and inventory information for the software testing life cycle.

How to use it

For an effective inventory system, use barcoding and mobile solutions. They can:

- conduct inventory counts.

- verify inventory

- adjust inventory

Benefit:

The benefits of using barcoding and mobile systems are ease, speed, and exactness. For instance, a barcode scanner makes inventory counts easier. It makes them quicker and more accurate. It’s better than counting.

5. System integrations

Inventory management software can connect to other business systems. These include accounting software, websites, and EDI, to name a few.

How to use it

Depending on the services your business uses, the system integrations necessary will differ. Examples of systems that can be integrated with your inventory management systems software include:

- Accounting software integration

- Web store integration

- 3PL and/or EDI integration

- Reporting software integration

Benefit:

By connecting to inventory management software, you can see inventory levels at a glance. This works across channels. These include physical stores, web stores, and phone orders. Then, you can examine inventory by area, warehouse, and item. This gives businesses better knowledge. It provides information for buying, sales, and inventory choices.

Ready to Build? Let’s Create Your Software Solution Today!

How Do You Choose The Best Software Development Company for Inventory Management Systems Development?

1. Consult Your Partners

Ask your accounting and ERP providers for suggestions. They have recommendations from years of working with SMBs. They can point you in the correct direction, especially with integration. The software needs a great deal of information from ERP systems. It needs something like once per day, or as businesses need it. That is because you need reliable information. Update it. It will help you make better custom software development consulting companies’ decisions and forecasts.

By consulting your partners, you end the barrier that incompatible systems bring. By asking their perspectives, you’ll have a waitlist of platforms. These platforms work with your existing systems.

2. Involve Your Community and Employees

While you have the option to make your own choice, seek advice and guidance from your SME communities. You’ve already researched and made a rundown of inventory management software. Communities can give you advice based on experience. A secure software development framework can help you thin down your choices even more. Another method for trimming down your rundown is by conversing with your employees. They’re your people on the ground. They can tell you which features are valuable for your daily operations.

3. Mind the Deployment Process

Choosing the right inventory software is another key decision driver. It depends on the deployment process. You need a provider that offers great customer support. They will help with deploying, testing, and maintaining their system. Investing in inventory software means assembling long haul vendor-client relationships. When vetting providers, pose these inquiries to identify the best fit:

- Are the pre-, during, and post-installation procedures well explained?

- Is customer support accessible?

- What do the past client reviews say about their service?

- Is onboarding training provided for your staff?

- Should you hire a freelancer to put the process in place for you?

4. Leverage Free Demos

One benefit of picking cloud-based solutions is getting free 14-day or 30-daytrials . Evaluating different platforms is a great method for learning which one turns out best for you. Yet, don’t get up to speed in this step. Try not to bounce at every free preliminary for an inventory system. These preliminaries are free, yet you invest time and integrate your system. Thus, you should pick platforms to use after the preliminaries for logistics inventory management.

Pro tip: Track every free trial you sign up for. Take a screenshot of the offer and mark it on your calendar when the trial ends. You don’t want to end up paying a full monthly fee for a platform you’re not happy with.

5. Opt for Future-Focused Options

Your inventory software ought to accomplish more than meet your current needs. It ought to likewise accommodate your future needs. In the event that you don’t feel that a long way ahead, you could have to switch systems after five years. Every custom software development service in USA aims for sustainable development. So consider your future business opportunities when picking a stage. The clients begin with a single product offering — for example, selling exercise gear. Then, over the years, they expanded their offerings. They do this by adding garden equipment and dinnerware to their items. At day’s end, they find it best to merge the information into one system for their business. They use one system instead of different ones for different pieces of the business. They end up searching for a better arrangement.

Future Trends and Innovations in Inventory Management Systems

Data-driven research provides innovation intelligence. It helps you improve decisions by giving an overview of new logistics technologies.

1. Omnichannel Inventory Control

Overseeing inventory across numerous sales channels is a top trend. It includes physical stores, online marketplaces, and web-based entertainment. The technology uses a ton of coordination and perceivability across all channels. Inventory management in logistics can move inventory between areas based on demand. It additionally lets warehouse managers track inventory levels in real-time. They can provide accurate information on demand and supply.

2. Cloud-based Management

Cloud-based inventory systems let businesses access their inventory information from anywhere. They can do as such whenever and on any device with an internet connection. This lets businesses manage their inventory in real time. They can make informed choices based on modern information and react to evolving markets. Cloud-based inventory systems are cheaper than on-premise ones. This is because they need less hardware and IT support. This trend in inventory management is predominant. It caters to businesses, everything being equal. This includes those who come up short on resources for expensive cloud solutions.

3. Predictive Inventory

Predictive inventory uses analytics and machine learning. It forecasts demand and optimizes inventory levels. This tech trend helps inventory managers predict future demand. They use verifiable information and market trends. This reduces the gamble of stockouts and overstocking. It likewise reduces the expense of inventory management.

Predictive inventory optimizes the supply chain. Moreover, by giving real-time information, it facilitates informed decision-production for managers regarding inventory and transportation. Consequently, this enhances efficiency and reduces costs while simultaneously ensuring customer fulfillment. This is achieved by guaranteeing the availability of the right items whenever they are needed.

4. Reverse Logistics

Reverse logistics involves overseeing items returned by customers. These items can be defective, damaged, or presently not needed by the customer. This trend is significant for Inventory Management Systems. Customers expect returns to be seamless and hassle-free. Great reverse logistics solutions enable high coordination and perceivability in the supply chain. It likewise facilitates businesses’ capacity to process returns and manage inventory levels. Effective reverse logistics processes cut the cost of returns and lift customer fulfillment. Inventory operators instrument them. Additionally, they reduce the environmental effect of transportation. They additionally reduce the effect of recycling or reusing returned items.

Conclusion

Master inventory management. It transforms challenges into chances for development, fulfillment, and benefit. In today’s digital age, leveraging technology is key to remaining competitive. It is a prime example of how technology can streamline operations, cut errors, and free up time. Remember, effective inventory management systems are a continuous process, not a one-time fix. Review your inventory practices. Remain updated on new tech. Be ready to adjust to changing customer needs and markets. With the right devices, you can change how you manage inventory. It can become a cornerstone of your store’s success.

Frequently Asked Questions (FAQs)

1. What is Inventory Management Systems?

Inventory management Systems involve tracking and controlling stock levels. The objective is to meet customer demand. This involves ordering, putting away, and selling items.

2. Why is inventory management important for stores?

Great inventory management prevents stockouts and overstocking. It improves income and customer fulfillment. It likewise enhances supplier relationships.

3. Can third-party inventory management systems software integrate?

Yes, outsider inventory management systems software can integrate with various other business systems seamlessly. Through APIs (Application Programming Interfaces) and integration capabilities, these systems can connect with accounting software, eCommerce platforms, POS (Point of Sale) systems, and that’s only the tip of the iceberg. This integration takes into consideration streamlined information stream, synchronized processes, and improved efficiency across different aspects of the business.

4. What features should I look for in inventory management systems software?

Look for multi-channel management. Also seek automated reordering, detailed analytics, easy integration, growth, inventory management in logistics, and cost-effectiveness.

5. How often should I review my inventory management practices?

Review your inventory practices. Make sure they are still effective. Also, make sure they adapt to new technology and respond to changing markets.