Supply chain inventory management stands at the cutting edge of transforming business operations in 2024, reshaping how organizations manage their resources, streamline operations, and fulfill customer needs. The business place is dynamic and cutthroat. Capable inventory management is basic. However, it drives success and keeps an upper hand. Imaginative advances, changing consumer preferences, and overall market shifts force businesses to adjust. They must adjust their inventory strategies to stay ahead.

In 2024, the significance of supply chain inventory management will turn out to be considerably more clear. This will be shown by shocking statistics. A report by McKinsey says worldwide internet business sales are projected to reach $6.5 trillion by 2023. This shows the huge volume of goods moving through supply chains around the world. Besides, the Coronavirus pandemic has brought unprecedented disruptions to supply chains, emphasizing the requirement for coordinated and resilient inventory management softwares practices. The National Retail Federation estimates that U.S. retailers lose approximately $224 billion due to out-of-stock items, further emphasizing the basic job of inventory management in supply chain in fulfilling customer needs and expanding sales opportunities.

We will investigate how supply chain inventory management is changing business in 2024. It involves using progressed tech to advance inventory levels. This boosts proficiency and profits. We will investigate the strategies, trends, and best practices shaping the future of inventory management. We will give insights and tips to businesses. They seek to flourish in the steadily impacting universe of supply chain management. Go along with us as we investigate the changing job of supply chain inventory management. It will immensely affect business operations in 2024 and then some.

| [[Infographic Content]] |

Understanding Supply Chain Inventory Management

Inventory and supply chain management is a basic part of current business operations, encompassing the processes and strategies used to oversee the progression of goods throughout the supply chain. With the worldwide economy becoming interconnected and consumer expectations advancing, viable inventory management has arisen as a critical differentiator for custom enterprise software development companies seeking to keep up with competitiveness and benefit. In this section, we will dig into the intricacies of supply chain inventory management, investigating its significance, challenges, and strategies for improvement.

Importance of Efficient Inventory Management

Effective inventory management is essential for ensuring that the perfect products are accessible at the ideal overall setting, limiting stockouts and excess inventory. As per the National Retail Federation, inventory inaccuracies can prompt a loss of up to 2% of annual sales revenue, featuring the basic job of proficient inventory management in supply chain maximizing profitability.

1. Cost Reduction

Firstly, Productive inventory management cuts holding costs. They are for excess inventory and storage. It also reduces the risk of obsolescence and shrinkage. Enhancing inventory levels lowers businesses’ conveying costs. Furthermore, it also improves their monetary exhibition.

2. Maximizing Profitability

Secondly, Great inventory management boosts profits. It ensures that the right products are accessible when and where customers need them. By limiting stockouts and excess inventory, custom software development consulting companies can capture more sales opportunities and work on their main concern.

3. Enhanced Customer Satisfaction

Thirdly, Having products accessible on time is essential. It helps meet customer expectations and build dependability. Proficient inventory management ensures that customers can find the products they need when they need them. This leads to more joyful customers who make want more.

4. Operational Efficiency

Streamlining inventory and supply chain management processes improves functional effectiveness by reducing lead times, advancing request fulfillment, and limiting disruptions in the supply chain. Automating manual tasks and using best practices can boost productivity. They can also cut costs.

5. Adaptability to Market Changes

The present market is dynamic. Businesses must be coordinated and responsive to changes popular, supply chain disruptions, and recent fads. Proficient inventory management enables Custom Software Development Services USA to adjust to advertise dynamics, limiting risks and seizing valuable learning experiences.

6. Compliance and Risk Mitigation

You must adhere to safety guidelines and end dates. This is vital to keeping away from fines, penalties, and harm to your reputation. Great inventory management ensures accurate following and documentation of inventory. Lastly, it helps with consistence with regulations and reduces risk.

Ready to Build? Let’s Create Your Software Solution Today!

Key Components of Supply Chain Inventory Management

Supply chain inventory management involves overseeing the progression of goods from suppliers to customers. Ensuring that the ideal products are accessible with impeccable timing and spot is intricate, requiring careful preparation, coordination, and execution. However, these are to enhance inventory levels while cutting costs and boosting customer satisfaction. In this section, we will investigate the critical components of supply chain inventory management, shedding light on the fundamental elements that drive proficiency and effectiveness in overseeing inventory throughout the supply chain.

1. Demand Forecasting

Firstly, Request forecasting involves anticipating future interest for products. This is based on historical information, market trends, and different factors. Accurate interest forecasting is vital. It helps set stock levels well and keep away from stock outs or excess inventory. It also helps satisfy customer needs well.

2. Order Management

Secondly, Request management encompasses the processes engaged with getting, processing, and fulfilling customer orders. Effective request management ensures convenient request processing. It also ensures accurate request fulfillment and seamless communication. This communication is between suppliers, manufacturers, and customers.

3. Inventory Tracking and Visibility

Thirdly, Inventory following and visibility mean having the option to watch inventory levels. You can see where items are and the way in which they travel through the supply chain. Continuous inventory management softwares visibility enables businesses to go with informed choices, distinguish likely issues, and respond to changes popular or supply.

4. Supplier Collaboration

Supplier joint effort involves building strong relationships with suppliers. This is to ensure on-time deliveries, quality, and dependable supply chains. Working with suppliers helps businesses. It lets them upgrade inventory levels, reduce lead times, and cut supply chain risks.

5. Warehouse Management

Warehouse management focuses on streamlining warehouse operations to expand proficiency and productivity. Great warehouse management includes inventory storage, picking, pressing, and shipping. However, it also includes inventory association and layout improvement.

6. Technology Integration

Innovation is crucial in supply chain inventory management. It enables automation, information analytics, and constant visibility. Lastly, coordinating trend setting innovations such as inventory management in supply chain software, RFID, and standardized identification scanning systems streamlines inventory processes and enhances proficiency.

The Role of Technology in Inventory Management

Innovation is critical. It revolutionizes inventory management. It drives effectiveness, accuracy, and visibility in the supply chain. Innovation has progressed. Businesses can use it to beat old inventory challenges and stay serious in the present unique commercial center.

One of the vital roles of innovation in inventory management is automation. Automated inventory management systems influence software solutions to streamline processes such as request processing, inventory management softwares tracking, and replenishment. As per a study by McKinsey, automation can prompt a 20% reduction in supply chain costs and a half improvement in conveyance execution. Automating tasks cut errors. It also boosts productivity and accuracy. It lowers costs.

One more crucial aspect of innovation in inventory management is information analytics. Progressed analytics tools help businesses. They gain useful insights into inventory, request, and supply chain. IBM says businesses that use information analytics for inventory management can cut inventory costs by up to 10%. However, they can also further develop service levels by 20%. Information driven decisions let businesses advance inventory levels. They can also forecast interest and track down ways to further develop their supply chains.

Furthermore, innovation facilitates constant visibility and joint effort across the supply chain. RFID innovation, standardized tag scanning systems, and inventory management software give businesses ongoing access to inventory and supply chain management data, empowering them to follow inventory levels, watch shipments, and respond to changes in popular or supply. A report by Zebra Technologies says 78% of logistics companies concur. They say that continuous visibility into inventory levels is key for inventory management. Innovation enhances visibility and cooperation. Lastly, it lets businesses enhance inventory processes, cut stockouts, and fulfill customer needs.

The Vital Role of Efficient Supply Chain Inventory Management

Proficient inventory management is critical to successful businesses. It ensures smooth operations, upgraded resources, and blissful customers. The present worldwide commercial center is hyper-associated and fast-paced. The capacity to oversee inventory well is more crucial than any time in recent memory. It involves limiting costs. It also involves expanding revenue. Also, it involves upgrading customer satisfaction. The job of effective supply chain inventory management can’t be overstated. In this section, we will dive into the imperative job of productive supply chain inventory management, investigating its significance, challenges, and strategies for success.

1. Maximizing Profitability

Firstly, Effective inventory management affects an organization’s primary concern. It cuts holding costs, prevents stockouts, and boosts inventory turnover. The report is from Wasp Scanner tag Technologies. It says that effective inventory management raises profits by 35%.

2. Enhancing Customer Satisfaction

Secondly, Products must be accessible on time. This is key for meeting customer expectations and fostering devotion. Studies show that 76% of consumers are probably going to switch brands assuming they experience out-of-stock situations, featuring the significance of proficient inventory management in keeping up with customer satisfaction for many software Re engineering services.

3. Minimizing Costs

Thirdly, Poor inventory management can prompt excess inventory holding costs, increased storage expenses, and higher risks of obsolescence. The National Retail Federation estimates that U.S. retailers lose about $224 billion every year. However, this is due to out-of-stock items and excess inventory.

4. Optimizing Operational Efficiency

It reduces lead times. It improves request fulfillment. Furthermore, it enhances effectiveness. As per a study by McKinsey & Company, a custom software development agency USA that optimizes its supply chain operations can accomplish up to a 20% reduction in costs and a half improvement in conveyance execution.

5. Meeting Regulatory Compliance

You must keep the guidelines. They cover safety and end dates. Doing so is crucial. It prevents fines, penalties, and harm to reputation. Proficient inventory management ensures accurate following and documentation of inventory. It helps with consistent with rules.

6. Adapting to Market Dynamics

The present market is evolving. Businesses must be coordinated and responsive. They must respond to changes sought after, supply chain issues, and recent fads. Lastly, proficient inventory management software enables businesses to adjust to showcase dynamics, limiting risks and seizing valuable learning experiences.

| [[Infographic Content]] |

Common Challenges in Managing Supply Chain Inventory

Overseeing supply chain inventory is hard for businesses today. They face many challenges in the mind boggling and dynamic commercial center. Requests fluctuate. Supply chains break. Innovation limits. Beating these obstacles needs careful preparation. It needs strategic foresight and advancement. In this section, we will investigate some of the normal challenges looked by inventory management software for small businesses in overseeing supply chain inventory, shed light on their effect, and give insights into compelling moderation strategies.

1. Demand Variability

Firstly, Overseeing supply chain inventory is a major test. It is the changeability in customer interest. Requests can change from seasonal trends, promotions, or shifts in preferences. A study by Aberdeen Group found that 79% of companies see request fluctuation as a major inventory issue. Addressing request fluctuation requires robust forecasting techniques, cooperation with stakeholders, and nimble inventory and supply chain management processes. Businesses must use progressed request forecasting tools. They assist with anticipating request changes and enhance inventory. Using request driven strategies can help businesses. They respond well to changes in customer interest. This minimizes the risk of stockouts or excess inventory.

2. Supply Chain Disruptions

Secondly, Supply chains are disrupted by things like natural disasters, delays in transportation, or supplier issues. They pose enormous challenges to inventory management. Coronavirus showed that worldwide supply chains are vulnerable to unforeseen disruptions. This prompted widespread shortages and delays. A survey by the Business Continuity Institute found that 73% of organizations had supply chain problems in 2024. Moderating supply chain disruptions requires building resilience. We accomplish this by sourcing, diversifying suppliers, and making arrangements for contingencies. Businesses should make strong risk arrangements. They should invest in tech that boosts supply chain visibility and dexterity. Teaming up with suppliers and keeping up with open communication channels can help custom software development services USA alleviate the effect of supply chain disruptions on inventory management.

3. Inaccurate Data and Forecasting

Thirdly, Awful information and forecast errors lead to suboptimal inventory decisions. They cause stockouts, excess inventory, and greater expenses. Manual information section processes are mistake inclined. They lead to errors in inventory records and forecasting models. As per research by Gartner, unfortunate information quality costs custom software development consulting companies a normal of $15 million in lost revenue. Investing in better inventory management software and analytics tools can help businesses. They further develop information and forecasting accuracy. Using prescient analytics and machine learning can further develop request forecasting accuracy. However, it can also empower proactive inventory management. You must check and affirm inventory information. This is key for finding and fixing discrepancies in records.

4. Warehouse Management Challenges

Wasteful warehouse management leads to unfortunate inventory association. Individuals misplace items and use space. The Warehouse Education and Research Council says wasteful warehouse layouts can increase picking times. They can do as such by up to 30%. However, restricted visibility into warehouse operations and inventory movements further exacerbates warehouse management challenges. Carrying out warehouse management systems (WMS) and scanner tag scanning innovation can further develop hospital inventory management software accuracy and streamline warehouse operations. Improving warehouse layout and work process design can cut travel time. It can also bring down work costs and boost warehouse productivity. Investing in representative preparation and execution management can further develop labor force productivity. It can also reduce errors in warehouse operations.

5. Obsolete Inventory Management

Overseeing obsolete inventory is quite difficult for businesses. Obsolete items tie up capital and occupy valuable warehouse space. An APICS study found that businesses hold 20% to 30% of their inventory as excess or obsolete. Obsolete inventory can emerge out of innovation changes. It can also come from product obsolescence or shifts in consumer tastes. Great inventory obsolescence policies and regular audits can help. They can help businesses find and sell obsolete inventory. Carrying out unique valuing strategies and offering discounts for some warehouse inventory management software on obsolete items can assist businesses with recuperating some of the sunk costs associated with obsolete inventory. Businesses can team up with suppliers. They can arrange adaptable terms and pursue buyback or return agreements for excess and obsolete inventory. Doing this can moderate the monetary effect.

6. Supplier Relationship Management

It is crucial to Oversee relationships with suppliers. They ensure opportune deliveries, quality, and supply chain dependability. The Institute for Supply Management says that suppliers cause 60% to 80% of supply chain disruptions. Terrible communication, untrustworthy suppliers, and quality issues can disrupt inventory streams. Moreover, they can also hurt production schedules. Creating strategic partnerships with dependable suppliers and fostering open communication channels for inventory management system can assist with alleviating supplier-related challenges. Using supplier metrics and doing regular evaluations can track down areas for development. They can also drive continuous improvement. Investing in supplier joint effort platforms and digital procurement tools can streamline communication. Lastly, they also further develop transparency and strengthen supplier relationships.

Unlock Your Business Potential with Custom Software Solutions. Contact us Today!

Strategies for Optimizing Supply Chain Inventory Levels

Businesses must upgrade inventory levels. This is key for proficiency, cost-cutting, and pleasing customers. With the steadily changing demands of the market and the complexities of worldwide supply chains, custom enterprise software development companies must embrace strategic approaches to ensure that inventory levels are lined up with requests while limiting excess stock. In this section, we will investigate ways to streamline supply chain inventory levels. We will give insights into demonstrated techniques and best practices.

1. Demand Forecasting

Firstly, Request forecasting involves anticipating future interest for products. This is based on past sales, market trends, and other key factors. Accurate interest forecasting lets businesses expect customer interest. Moreover, they can then adjust inventory levels. This minimizes the risk of stockouts or excess inventory.

2. Safety Stock Optimization

Secondly, Safety stock refers to the buffer inventory held to alleviate the risk of stockouts due to request fluctuation or supply chain disruptions. Advancing safety stock levels involves adjusting costs and risk. You must convey enough inventory to satisfy unexpected need or supply disruptions.

3. Just-in-Time (JIT) Inventory Management

Thirdly, JIT inventory management minimizes inventory by syncing production and inventory with customer interest. By reducing excess inventory and conveying costs, JIT inventory management in supply chain helps businesses further develop effectiveness, cut waste, and respond to changes popularly.

4. ABC Analysis

ABC analysis categorizes inventory items based on their value and contribution to sales revenue. Businesses should focus their inventory efforts on high-value items (A-items). They should focus on low-value items (C-items). This focus lets businesses streamline inventory levels and resource allotment.

5. Supplier Collaboration

Businesses appreciate teaming up with suppliers. It helps them upgrade inventory levels, cut lead times, and further develop supply chain unwavering quality. However, sharing interest forecasts, inventory data, and production schedules with suppliers helps. It lets businesses ensure ideal deliveries and cut excess inventory.

6. Continuous Improvement

We check and enhance inventory processes to track down inefficiencies. Then, we put set up remedial actions. By fostering a culture of continuous improvement, businesses can adjust to evolving markets. Lastly, they can also boost inventory accuracy and further develop supply chains.

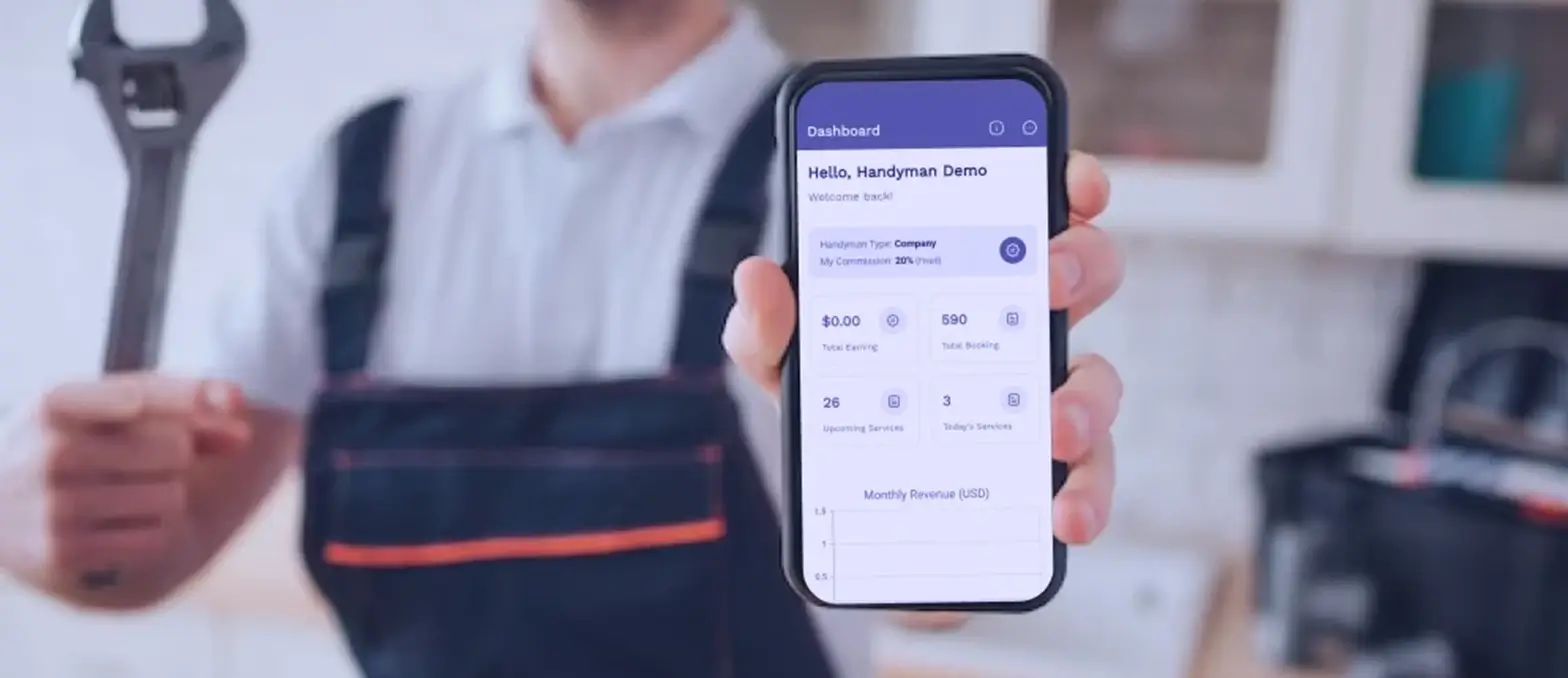

Harnessing Technology to Enhance Supply Chain Inventory Management

Today, in the digital age, innovation is a key power. It is revolutionizing the way in which we oversee supply chain inventory. Businesses are using innovation to further develop how they oversee inventory in the supply chain. They use advanced software and new following tech. These boost visibility, accuracy, and productivity. In this section, we will investigate how businesses can harness innovation to enhance supply chain inventory management, giving insights into the transformative effect of innovation on streamlining processes and further developing supply chain execution.

1. Inventory Management Software

Firstly, Inventory management software solutions give businesses brought together platforms. They use them to follow, make due, and break down inventory data. The software solutions offer features like constant inventory following, request forecasting, request management, and revealing. They let businesses settle on data-driven choices and advance inventory.

2. RFID Technology

Secondly, RFID innovation uses radio waves to ID and track inventory. It does this throughout the supply chain. RFID tags are joined to inventory items. Therefore, they can be scanned. This provides ongoing visibility into inventory levels, locations, and movements. It also minimizes manual data section errors.

3. Barcode Scanning Systems

Thirdly, Standardized identification scanning systems empower businesses to follow inventory items using scanner tag labels and handheld scanners. By scanning standardized identification labels, businesses can record inventory transactions. Furthermore, they can also follow inventory movements and update inventory records continuously. This improves accuracy and proficiency in inventory management.

4. Internet of Things (IoT) devices

IoT devices, such as sensors and smart devices, can be sent throughout the supply chain to watch ecological conditions, track inventory management softwares levels, and upgrade warehouse operations. Therefore, the devices give constant data on factors like temperature, humidity, and storage conditions. They let businesses ensure product quality, forestall spoilage, and upgrade inventory storage.

5. Cloud Computing

Cloud-based inventory management softwares systems offer scalability, adaptability, and accessibility, permitting businesses to access inventory data and analytics from any area with a web association. Businesses can use cloud computing to unify inventory data. They can also use it to work with stakeholders and interface with other business systems. This makes inventory management processes simpler and improves coordinated effort across the supply chain.

6. Data Analytics and Artificial Intelligence (AI)

Data analytics and simulated intelligence tech let businesses investigate lots of inventory data. They track down patterns and anticipate future interest. Businesses can use computer based intelligence controlled algorithms and prescient analytics. Therefore, they can use them to upgrade inventory levels, reduce stockouts, and further develop inventory turnover rates. Lastly, this enhances supply chain productivity and customer satisfaction.

| [[Infographic Content]] |

Implementing Best Practices for Supply Chain Inventory Management

Executing best practices for supply chain inventory management is crucial for businesses seeking to advance their hospital inventory management software levels, work on functional productivity, and upgrade customer satisfaction. Businesses can use demonstrated strategies and methods. They can simplify inventory processes. Therefore, they can cut costs and reduce risks in the supply chain. In this section, we will investigate the significance of using best practices for supply chain inventory. We will also give insights into key strategies to success.

1. Inventory Segmentation

Firstly, Inventory segmentation involves classifying inventory items based on their value, request changeability, and criticality to the business. Segmenting inventory lets businesses focus on management. They can assign resources well and upgrade inventory to satisfy customer needs.

2. ABC Analysis

Secondly, ABC analysis is a technique used to classify inventory items. It’s based on their significance and contribution to sales. Focusing on high-value items (A-items) is vital. It lets businesses improve inventory management and resource portion by limiting regard for low-value items (C-items).

3. Supplier Collaboration

Thirdly, It is essential to Work with suppliers. It ensures on-time deliveries, quality, and solid supply chains. However, businesses can share request forecasts, inventory data, and production schedules with suppliers. This helps them cut lead times, cut costs, and further develop inventory accessibility.

4. Lean Inventory Management

Lean inventory management focuses on cutting waste. Furthermore, it also aims to reduce excess inventory. It optimizes inventory levels to match customer interest. By executing rest principles on warehouse inventory management software such as just-in-time (JIT) inventory management, businesses can further develop effectiveness, reduce costs, and improve responsiveness to advertise changes.

5. Continuous Improvement

Further developing means evaluating and improving inventory processes. This is to find and fix inefficiencies. By fostering a culture of continuous improvement, custom enterprise software development companies can adjust to changing economic situations, further develop inventory accuracy, and upgrade supply chain execution.

6. Use of Technology

You can use cutting edge innovations like inventory software, RFID, and standardized tag scanners. They can make inventory processes faster, further develop visibility, and increase accuracy. Businesses can invest in tech solutions custom fitted to their needs. Lastly, this can automate manual tasks, cut errors, and give ongoing insights into inventory.

Transform Your Software Vision into Reality – Book A 30 Minutes Free Consultation!

Key Performance Indicators (KPIs) for Evaluating Supply Chain Inventory Management

KPIs are basic. They check the effectiveness and proficiency of supply chain inventory management. By following key metrics, businesses can assess their presentation. However, they can track down areas to improve and use data to advance inventory and processes. In this section, we will investigate key execution indicators for evaluating supply chain inventory management, giving insights into the metrics that make the biggest difference for assessing inventory execution and driving continuous improvement.

1. Inventory Turnover Ratio

Firstly, The proportion measures how often inventory is sold or used inside a specific period. It shows how inventory is made due. A high turnover proportion suggests inventory sales. A low proportion might mean excess or slow items.

2. Inventory Accuracy

Secondly, Inventory accuracy measures the hole between the physical inventory count and the inventory records. It shows how solid the inventory data is. High inventory accuracy is crucial. It minimizes stockouts and cuts excess inventory. It also ensures accurate monetary detailing.

3. Stockout Rate

Thirdly, The stockout rate measures how frequently inventory is unavailable. It shows the level of times this happens. It leads to lost sales. Following stockout rates helps businesses find inventory issues. It also helps them further develop service levels.

4. Fill Rate

The fill rate measures the level of customer orders that are fulfilled from accessible inventory. However, it shows how well businesses satisfy customer needs. A high fill rate shows that businesses oversee inventory well. They also meet customer expectations.

5. Order Cycle Time

Request process duration measures how long it takes to process a request. This includes picking, pressing, and shipping it to the customer. Checking request process duration helps businesses track down bottlenecks all together. However, it also helps them further develop productivity.

6. Inventory Carrying Cost

Inventory conveying costs are the expenses of holding and storing inventory. They include storage costs, insurance, and obsolescence. Observing hospital inventory management software conveying costs helps businesses streamline inventory levels and cut holding costs.

7. Supplier Performance

Supplier Performance metrics assess the dependability, quality, and timeliness of deliveries from suppliers. Observing suppliers’ exhibitions helps businesses recognize the best ones. However, it also helps them address issues with the worst ones.

8. Perfect Order Fulfillment

Perfect order fulfillment measures the level of customer orders that are followed through on time, complete, and without errors. Following wonderful request fulfillment helps businesses assess their supply chain. Lastly, it also shows customer satisfaction levels.

Emerging Trends in Supply Chain Inventory Management

The worldwide business landscape is evolving fast. Supply chain inventory practices are also changing a ton. They are changing to satisfy the needs of a unique market. Arising trends in supply chain inventory management are reshaping how custom software development outsourcing companies approach inventory enhancement, functional proficiency, and customer satisfaction. In this section, we will investigate some of the latest trends shaping the future of supply chain inventory management. Also, we will give insights into the new strategies and technologies driving change in the industry.

1. Demand Sensing and Forecasting

Firstly, Request sensing and forecasting use progressed analytics and continuous data. They foresee customer requests well. They adjust inventory to match evolving markets. Web based business and omnichannel retailing are rising. Request sensing and forecasting have become essential for businesses. They need to stay light-footed and responsive to shifting demands.

2. Blockchain Technology for Transparency and Traceability

Secondly, Blockchain innovation is building up momentum in supply chain inventory management. It provides transparency, detectability, and security for the development of goods. Blockchain records transactions on a distributed record. However, it lets businesses track inventory movements, confirm product origins, and follow regulations.

3. Internet of Things (IoT) and Sensor Technology

Thirdly, IoT devices and sensor innovation are revolutionizing inventory management in supply chain by empowering ongoing observation of inventory levels, natural conditions, and asset following. IoT devices are implanted in warehouses, vehicles, and products. They let businesses further develop inventory visibility, improve storage, and forestall stock outs or overstocking.

4. Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms are used to break down lots of data. They track down patterns, trends, and anomalies in inventory. However, by utilizing man-made intelligence fueled forecasting models and prescient analytics, custom software development services can upgrade inventory levels, reduce holding costs, and further develop request forecasting accuracy.

5. Robotics and Automation

Robotics and automation are evolving warehouses. They automate dull tasks like picking, pressing, and sorting. Businesses can use autonomous mobile robots (AMRs) and mechanical arms. With them, they can increase warehouse throughput, cut work costs, and boost proficiency.

6. Sustainability and Green Logistics

Sustainability and ecological considerations are becoming significant in supply chain inventory management, driving businesses to embrace green logistics practices. They are cutting packaging waste while streamlining transportation routes. Moreover, they are tracking down ways to shrink their carbon impression and advance sustainability, which are all being finished across the supply chain.

7. Collaborative Supply Chain Networks

Collaborative supply chain networks let businesses work together with suppliers, partners, and customers. They do this to upgrade inventory levels, share resources, and further develop supply chain spryness. However, by cooperating and sharing data, businesses can increase visibility. Lastly, They can also cut lead times and reduce risks in the supply chain.

| [[Infographic Content]] |

Concluding Thoughts: Driving Success Through Effective Supply Chain Inventory Management

Overseeing supply chain inventory well is vital. It’s essential for success in the present cutthroat business world. By using best practices and new tech, and staying mindful of trends, businesses can unlock many benefits. These benefits help their success and development.

Advancing inventory levels cuts conveying costs. It also boosts effectiveness and customer satisfaction. As per research by the Aberdeen Group, companies with best-in-class hospital inventory management software accomplish 90% inventory accuracy and 95% request fulfillment rates, prompting significant cost savings and further developed service levels.

Also, great inventory management lets businesses adjust. It lets them adjust to changing markets and customer demands. Businesses can see inventory levels and request patterns progressively. They can use this data to settle on smart decisions and stay away from stockouts. However, they can also make the most of sales opportunities. A study by McKinsey & Company found that companies that invest popular forecasting and inventory improvement see up to a 15% boost in revenue development.

Also, supply chain resilience and readiness are crucial. They assist with reducing risks and keep business running. By teaming up with suppliers, improving transportation routes, and embracing adaptable inventory strategies, custom software development organization in USA can respond to disruptions and keep a strategic advantage. Also, research reveals that companies with resilient supply chains experience 20% higher net revenues contrasted with their peers.

Overseeing supply chain inventory well is critical to business success. It helps companies cut costs, work better, and please customers. However, by embracing development and fostering cooperation. Also, by refining their inventory practices. Businesses can set themselves up for long haul development and success in an evolving commercial center.

Exploring Supply Chain Inventory Management: Frequently Asked Questions

1. What is Supply Chain Inventory Management, and Why is it Important?

In supply chain inventory management, you oversee the progression of goods. They go from suppliers to customers. It ensures the perfect products are accessible at the ideal overall setting. It is crucial for upgrading inventory management softwares levels, reducing costs, and fulfilling customer needs. Great inventory management helps businesses in 3 ways. At long last, it reduces stockouts and excess inventory.

2. What are The Common Challenges Businesses Face in Inventory Management?

Inventory management faces normal challenges. These include shifting interest and supply disruptions. Also, inaccurate forecasting, wasteful warehouses, and overseeing obsolete inventory. Suppliers are sometimes slow. Inventory data is many times wrong. These issues can cause excessively or excessively minimal stock. This hurts customer satisfaction and profits.

3. How can Businesses Optimize Inventory Levels in The Supply Chain?

Custom software development outsourcing companies can advance inventory levels by taking on strategies such as request forecasting, safety stock enhancement, just-in-time (JIT) inventory management, and inventory segmentation. Businesses can offset inventory costs with the need to fulfill customer needs. They do this with cutting edge tech. At long last, they also work with suppliers. What’s more, they continue to further develop inventory processes.

4. What Role Does Technology Play in Supply Chain Inventory Management?

Innovation is crucial in supply chain inventory management. It provides tools and solutions for following inventory. It also does forecasting for request. What’s more, it manages warehouses. What’s more, it does data analytics. Technologies like RFID, standardized identification scanners, and artificial intelligence help businesses. They further develop visibility, accuracy, and proficiency in overseeing inventory across the supply chain.

5. How can Businesses Measure The Effectiveness of their Inventory Management Practices?

Businesses can measure the effectiveness of their inventory management in supply chain practices using key execution indicators (KPIs) such as inventory turnover proportion, inventory accuracy, stockout rate, fill rate, request process duration, inventory conveying cost, supplier execution, and wonderful request fulfillment. At long last, by following these metrics, businesses can assess their presentation. They can track down areas to improve and advance inventory.