Inventory management remains as a foundation in supply chain tasks, applying a significant impact on the efficiency, cost-effectiveness, and overall success of businesses worldwide. With Worldwide Inventory Management in Supply Chain turning out to be progressively complicated and interconnected, the requirement for hearty inventory management rehearses has never been more basic. According to the Inventory Accuracy and Shrinkage Study, led by the National Retail Federation, the typical inventory precision rate across retail areas floats around 63%. Moreover, Utilizing artificial intelligence in software development, a concentrate on Inventory Management and Optimization in Retail found that conveying costs can represent up to 25-30% of an organization’s overall inventory venture.

In addition, the significance of inventory management reaches out a long way past simple cost contemplations. In the present hypercompetitive commercial center, where customer expectations are constantly developing, inventory management fills in as a key part for fulfilling purchaser needs in an opportune and effective way. A review by PwC uncovered that an astounding 65% of purchasers expect custom software development services in USA to guarantee the items they want are available at whatever point they need them. Failure to measure up to these assumptions can bring about disappointed customers, lost deals, amazing open doors, and hopeless harm to mark notoriety.

In this unique situation, this investigation into the fundamental job and significance of inventory management in supply chain success becomes foremost. By diving into the key standards, demonstrated systems, and arising advancements forming present day inventory management rehearses, custom software development consulting companies can situate themselves to explore the intricacies of the supply chain scene with certainty and versatility. From upgrading inventory levels and utilizing progressed investigation to carrying out state of the art inventory management software solutions.

| [[Infographic Content]] |

Understanding Inventory Management in Supply Chain

Inventory management is the orderly course of directing and controlling the progression of merchandise into and out of an association’s inventory. With regards to the supply chain, it refers to the careful management of inventory levels at different stages, from natural substances and work underway to completed merchandise awaiting appropriation.

This critical aspect of supply chain management includes a horde of interconnected undertakings, including determining request, obtainment, stockpiling, and inventory optimization. At its center, compelling inventory management aims to figure out some kind of harmony between maintaining adequate stock levels to satisfy customer needs while limiting inventory and related costs.

The environment of custom software development outsourcing, described by fast globalization, unstable economic situations, and consistently changing buyer inclinations, the significance of productive inventory management couldn’t possibly be more significant. Studies show that businesses regularly tie up a huge part of their capital in inventory, making it basic to enhance inventory levels to expand benefit.

The rise of e-commerce and omnichannel retailing has introduced new complexities to inventory management, necessitating agile and adaptive approaches to meet the demands of modern consumers. Timely and accurate inventory management upgrades functional efficiency as well as straightforwardly influences customer fulfillment and brand notoriety.

Custom software development services USA can open doors for cost reserve funds, further developed efficiency, and upper hand in the present unique commercial center. Whether through the reception of cutting edge inventory management advances, execution of best practices, or optimization of inventory renewal methodologies, dominating inventory management is fundamental for driving supply chain success.

Ready to Build? Let’s Create Your Software Solution Today!

What is Inventory Management in the Supply Chain?

Inventory management in supply chain management alludes to the efficient coordination and control of products and materials streaming inside an organization’s supply organization. It includes a progression of key choices and functional cycles aimed at upgrading inventory levels, guaranteeing the availability of items when required, and limiting conveying costs.

Data from the National Retail Federation’s Inventory Precision and Shrinkage Study reveals that the typical inventory exactness rate across retail areas floats around 63%. This accentuates the unavoidable difficulties inventory management software for small businesses face in maintaining exact command over their inventory levels. Inefficient inventory management contributes essentially to overabundance conveying costs, with the Inventory Management and Optimization in Retail survey uncovering that conveying costs can represent up to 25-30% of an organization’s overall inventory speculation.

Viable inventory management includes guaging request, deciding fitting stock levels, and decisively situating inventory all through the supply chain. By utilizing authentic deals data, market patterns, and request figures, businesses can upgrade inventory levels to satisfy customer needs while limiting overabundant inventory and related costs.

Besides, inventory management assumes an essential part in guaranteeing smooth tasks across different phases of the supply chain, from obtainment and creation to warehousing and circulation. As per a survey conducted by PwC, 65% of consumers anticipate that businesses should have the items they want available when they need them. Failure to live up to these assumptions can bring about disappointed customers, lost deals, potential open doors, and harm to mark notoriety.

Overall, effective inventory management in the supply chain is fundamental for expanding productivity, meeting customer expectations, and gaining an upper hand in the commercial center. By carrying out strong inventory management practices and utilizing creative advancements, businesses can smooth out tasks, lessen costs, and drive sustainable development.

Why is Inventory Management Crucial for Supply Chain Success?

Inventory management is critical for supply chain success because of its immediate effect on functional efficiency, cost control, and customer fulfillment. Powerful inventory management guarantees that the right amount of items is available with perfect timing and spot, in this way limiting stockouts and overabundance inventory. Data from the Inventory Management and Optimization in Retail survey demonstrates that conveying costs can represent up to 25-30% of an organization’s overall inventory venture. By advancing inventory levels, businesses can diminish conveying costs and let loose capital for different ventures.

Besides, inventory management assumes a critical part in satisfying customer needs and maintaining high help levels. As per a survey conducted by PwC, 65% of consumers expect custom software development companies in USA to have the items they want available when they need them. Failure to measure up to these assumptions can bring about disappointed customers, lost deals open doors, and harm to mark notoriety.

Additionally, effective inventory management adds to smoothed out activities and further developed supply chain perceivability. Businesses can utilize advanced inventory management advancements like RFID (Radio-Recurrence Recognizable proof) and IoT (Internet of Things). They can utilize them to follow inventory continuously, track down failures, and go with data-driven choices. As per a report by McKinsey, companies with cutting edge supply chain perceivability accomplish on normal 20% higher inventory turnover and 19% higher request satisfaction rates.

Moreover, inventory management empowers businesses to adjust to changing economic situations and alleviate gambles. The present business is dynamic. It’s portrayed by globalization and supply chain interruptions. Agile inventory management is fundamental for flexibility and intensity. By following inventory levels, tracking down potential bottlenecks, and making reinforcement arrangements, custom software development consulting can cut chances. They can likewise respond to showcase changes.

Benefits of Implementing Effective Inventory Management Practices

Implementing effective inventory management in supply chain practices offers many benefits. Businesses work in the mind boggling scene of supply chains. Advancing inventory management has huge benefits. It sets aside cash and further develops customer satisfaction. We should dig into these benefits through a progression of central issues:

1. Cost Reduction

Proficient inventory management in supply, first and foremost, chain management limits conveying costs related with abundance inventory while decreasing the risk of stockouts. The Inventory Management and Optimization in Retail survey says that conveying costs can be 25-30% of an organization’s inventory. Great inventory management brings down conveying costs. It does this by cutting overabundance inventory and utilizing extra room well.

2. Improved Cash Flow

Also, By streamlining inventory levels, businesses can let loose capital that would somehow or another be restricted in abundance inventory, further developing cash flow. A survey by the Supply Chain Management Survey found that companies with great inventory practices see a 20-half reduction in conveying expenses. This leads to better cash flow. By enhancing inventory levels, custom software development outsourcing companies can guarantee capital isn’t restricted in overabundance inventory, permitting them to effectively allocate resources more.

3. Enhanced Customer Satisfaction

Thirdly, Precise inventory management guarantees item availability, leading to improved customer satisfaction and reliability. Research demonstrates that 81% of customers will pay more for a better customer experience. Precise inventory management guarantees item availability. It decreases the risk of stockouts and rainchecks. This improves customer satisfaction and dependability.

4. Increased Efficiency

Easier inventory processes lessen manual blunders. They likewise enhance extra room and request satisfaction. The Aberdeen Group expresses companies with upgraded inventory management have a 95% accuracy rate. This is contrasted with 65% for companies with unfortunate inventory practices. Working on inventory management cuts blunders. It additionally saves space and paces up request satisfaction.

5. Better Decision Making

Admittance to continuous inventory data empowers informed decision-making, assisting businesses with answering changing business sector requests. Ongoing inventory data helps custom software development companies in USA go with informed choices. They can use it for inventory restocking, creation planning, and request forecasting. A survey by Gartner found that companies with constant inventory data can answer 20% quicker to showcase changes. This is contrasted with those with obsolete inventory frameworks.

6. Minimized Risk

Effective inventory management mitigates the risk of old inventory, stockouts, and supply chain disturbances, upgrading strength. Wasteful inventory management expands the risk of stockouts, overabundance inventory, and outdated nature. By utilizing great inventory management, businesses can diminish these risks. They can likewise further develop supply chain versatility and acclimate to showcase changes.

7. Improved Forecasting Accuracy

Authentic inventory data and request estimates assist with more exact inventory arranging and forecasting. Authentic inventory data and request conjectures let businesses anticipate future interest. They can then change inventory levels. The Establishment of Business Forecasting and Arranging says that companies with precise estimates see a 15-20% expansion.

8. Reduced Lead Times

Effective inventory management abbreviates lead times. It guarantees unrefined substances and parts are available when required. Great inventory management abbreviates lead times. It guarantees that natural substances and parts are available when required. APICS did a review. It found that companies that use without a moment to spare inventory see a half cut in lead times.

9. Optimal Resource Use

By cutting overabundance inventory and raising inventory turnover, best software consulting companies can advance how they use resources. By cutting abundance inventory and raising inventory turnover, businesses can use resources better. A report by McKinsey says that companies that further develop their inventory turnover have 20% higher rates. They likewise have 15% lower holding costs.

10. Competitive Advantage

Involving progressed inventory management in supply chain management assists businesses with gaining an edge. It does as such by further developing efficiency, reducing expenses, and satisfying customers. The practices empower businesses to gain a competitive advantage. They do this by further developing efficiency, reducing expenses, and supporting customer satisfaction. A survey by the Harvard Business Survey found that companies that succeed in inventory management show improvement over their friends. They beat them by 73% in income development and by 12% in profitability.

Unlock Your Business Potential with Custom Software Solutions. Contact us Today!

Strategies for Efficient Inventory Management in Supply Chain

Productive inventory management is critical to supply chain optimization. It is a key part for functional greatness and cost investment funds. The present business climate is dynamic. It is set apart by globalization, changing buyer inclinations, and supply chain interruptions. Businesses should use systems to guarantee products flow while limiting costs. By implementing robust software development lifecycle security practices, companies can gain ongoing experiences into their supply chains, empowering them to streamline inventory levels and alleviate likely disturbances.

1. Demand Forecasting

Firstly, Exact interest forecasting fills in as the establishment for effective inventory management. The Institute of Business Forecasting and Planning did a study. They found that companies with exact interest conjectures see a 15-20% increment in figure accuracy. Businesses can use past deals data and market patterns. They can likewise use progressed investigation to estimate requests better. This cuts the risk of stockouts and overabundance inventory.

2. ABC Analysis

Besides, ABC examination arranges things in inventory into three classifications. The classifications depend on their worth and commitment to deals. The Pareto Principle expresses 80% of deals come from 20% of things (A things). This shows the need to zero in on inventory management in supply chain. By focusing resources on high-value items (A things), and involving severe controls for low-esteem things (C things). Businesses can further develop inventory and efficiency.

3. Just-in-Time (JIT) Inventory Management

Thirdly, JIT inventory management aims to reduce inventory expenses. It does this by synchronizing creation and inventory levels with customer interest. A survey by APICS found that companies that use JIT inventory management have 50% shorter lead times. It diminishes overabundant inventory and conveying costs. JIT supports cash flow, efficiency, and the capacity to respond to advertise changes.

4. Vendor-Managed Inventory (VMI)

VMI shifts inventory management in the supply chain. It shifts it from the purchaser to the provider. It allows providers to follow and restock inventory for the purchaser. The University of Tennessee found that companies utilizing VMI drives cut inventory by 20-30%. They likewise saw a 5-10% lift in inventory turns. VMI cultivates nearer joint effort among purchasers and providers. It further develops supply chain perceivability, cuts stockouts, and helps efficiency.

5. Safety Stock Optimization

Security stock is a cradle. It safeguards against unforeseen interest changes or supply disturbances. Yet, keeping a lot of security stock raises conveying costs and causes inventory out of date quality. Inventory management software for small businesses can use factual models, recreation strategies, and risk investigation apparatuses. They use them to cut risk and amplify efficiency by setting optimal wellbeing stock levels.

6. Inventory Turnover Improvement

Inventory turnover estimates the recurrence at which inventory is sold and supplanted inside a particular period. By and large, 20% higher turnover rates and 15% lower holding costs. To further develop inventory turnover, you can cut lead times, upgrade request sizes, and use lean inventory management.

7. Use of Advanced Technologies

Finally, RFID, IoT, and inventory software show inventory levels. They show supply chain activities progressively. They are cutting edge innovations. McKinsey did a review. It found that companies with better supply chain perceivability have 20% higher inventory turnover. They additionally have 19% higher request satisfaction rates. Custom software development services USA are enabled by these advances to accomplish more noteworthy accuracy in inventory and request forecasting, while likewise smoothing out overall inventory management processes.

Businesses can use these ways to deal with improving inventory management in supply chain practices. This will diminish costs and give them a competitive advantage in the present unique commercial center.

| [[Infographic Content]] |

Key Components of Inventory Management in Supply Chain

Managing inventory is complex. It is essential for smooth supply chains in numerous ventures. It incorporates many key parts. They assist with proficient inventory taking care of, stockpiling, and development. Understanding these parts is key for businesses. They need to advance their inventory management and further develop supply chain execution. We should investigate the critical parts of inventory management in supply chain through a progression of concise points:

1. Demand Forecasting

Right off the bat, Exact interest forecasting fills in as the foundation of effective inventory management. By taking a gander at past deals, market patterns, and customer inclinations, custom software development consulting companies can foresee requests. Then, at that point, they can change inventory levels.

2. Inventory Planning and Replenishment

Secondly, Inventory arranging includes setting the best inventory levels. The levels depend on request figures, lead times, and administration objectives. Recharging procedures guarantee convenient restocking. They forestall stockouts and limit abundance holding costs.

3. Inventory Classification

Thirdly, Inventory is arranged by ascribes like worth, request changeability, and lead time. Normal characterization strategies incorporate ABC examination. It sorts things as high-esteem (A), medium-esteem (B), or low-esteem (C) in light of their deal commitment.

4. Warehouse Management

Effective warehouse management is fundamental for enhancing inventory capacity, association, and recovery. Key warehouse management exercises incorporate inventory getting, picking, pressing, and transportation.

5. Inventory Tracking and Control

Inventory following includes watching the development and area of inventory things. This occurs all through the supply chain. Inventory control measures incorporate standardized tag filtering, RFID innovation, and cycle counting. Custom software development outsourcing companies guarantee inventory accuracy and forestall shrinkage.

6. Order Fulfillment

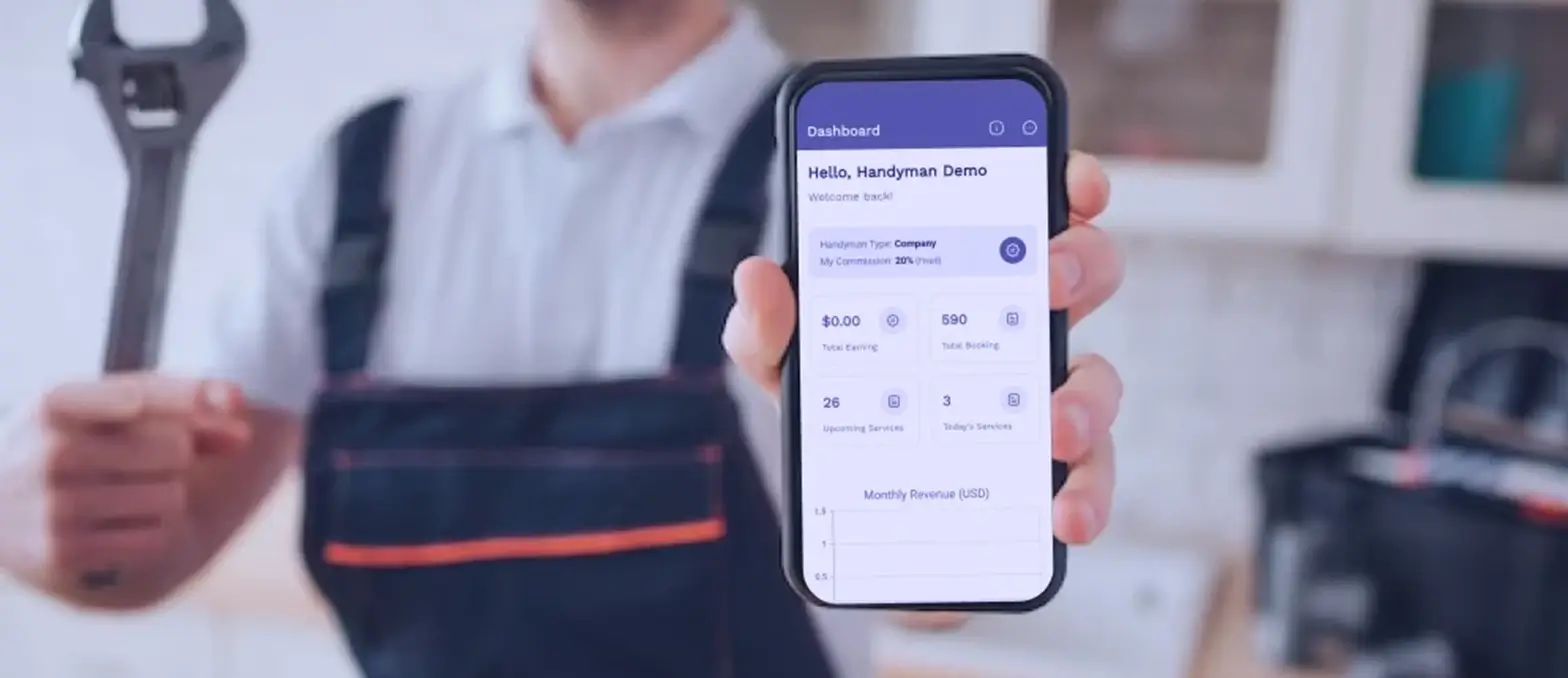

Inventory management software assumes a basic part in smoothing out request satisfaction processes. By working on request picking, pressing, and delivery, these software solutions can guarantee businesses fulfill customer needs and maintain high help levels.

7. Inventory Optimization

Inventory optimization aims to adjust inventory venture and administration level prerequisites. These strategies incorporate financial request amount (EOQ) examination. They likewise cover wellbeing stock optimization and reorder point computation. They diminish conveying costs while guaranteeing sufficient inventory.

8. Supplier Management

Effective supplier management is crucial for maintaining solid and responsive supply chains. Working intimately with providers guarantees convenient conveyances. It additionally guarantees quality confirmation and cost-effective obtainment of inventory things.

9. Technology Integration

Utilizing progressed supply chain tech, similar to inventory software, IoT sensors, and prescient investigation, further develops perceivability and command over inventory. Adding tech to supply chain frameworks helps share data and go with choices continuously.

10. Continuous Improvement

Ultimately, Consistent improvement includes continuous appraisal and optimization of inventory management processes. Businesses adjust to changing business sectors by utilizing criticism. They do assessments and take on best practices. They likewise drive persistent improvement in inventory management in supply chain management.

Focusing on these key parts can help businesses. They can be major areas of strength for making practices. These practices support proficient supply chains and drive business success.

Techniques for Optimizing Inventory Levels

Upgrading inventory levels is essential in supply chain inventory management. It includes keeping the right equilibrium. You should maintain sufficient stock to fulfill customer needs and try not to hold a lot of additional inventory, which is costly. Businesses in all enterprises face the test of overseeing inventory levels well. This is vital to great activities and high benefits. Involving numerous methods can help custom software development companies in USA accomplish this equilibrium. It will likewise further develop their inventory management. We should investigate these procedures for improving inventory levels through a progression of central issues:

1. Demand Forecasting

Firstly, Accurate demand forecasting is essential. It decides the right inventory levels. To fulfill expected customer need, we really want these levels. By examining past deals, market patterns, and occasional examples, businesses can foresee future interest better.

2. Economic Order Quantity (EOQ) Analysis

Secondly, EOQ investigation helps custom software development outsourcing companies track down the best request amount. This amount limits the absolute cost of holding and requesting inventory. By adjusting requesting and holding costs, businesses can track down the best request amount. This amount limits all out inventory costs.

3. Safety Stock Optimization

Thirdly, Safety stock is a buffer. It safeguards against unforeseen interest changes or supply disturbances. Upgrading wellbeing stock levels includes surveying factors. These incorporate interest changeability, lead times, and administration level objectives. The objective is to adjust stock availability and cost.

4. Just-in-Time (JIT) Inventory Management

JIT inventory management aims to reduce inventory expenses. It does this by matching up creation and inventory levels with customer interest. JIT inventory management diminishes abundance inventory and conveying costs. Further developing cash flow in the supply chain, likewise upgrades tasks, permitting businesses to answer more effectively to changing business sector requests.

5. ABC Analysis

ABC examination arranges inventory of things. Warehouse inventory management software does this in light of their worth and their commitment to deals. To upgrade inventory, center around high-esteem things (A things). Likewise, use stricter controls for low-esteem things (C things).

6. Lead Time Reduction

Shortening lead times can diminish the requirement for additional wellbeing stock and cut inventory levels. This should be possible through better provider connections, more straightforward cycles, and proficient coordinated factors. By cutting lead times, businesses can better answer customer interest and further develop inventory turnover.

7. Continuous Monitoring and Change

Observing inventory levels, request examples, and economic situations helps businesses. It permits them to make opportune acclimations to inventory. By overseeing inventory, supply chains can answer changes in popularity or supply. This helps custom enterprise software development companies cut overabundance inventory and further develop turnover rates.

8. Technology Integration

Finally, Utilizing advanced inventory management tech, similar to inventory software, RFID, and IoT sensors, further develops perceivability. It likewise further develops command over inventory levels. Adding tech to supply chains allows them to share data continuously. Inventory management softwares additionally takes into account continuous decision-making. This empowers businesses to improve inventory levels more.

Businesses can use these methods to streamline inventory levels. This will upgrade supply chain efficiency, cut costs, and lift customer satisfaction. Utilizing a blend of these procedures can help businesses. Tailor them to explicit business needs. This can assist businesses with turning out to be more agile and competitive in the present quick market.

| [[Infographic Content]] |

Technologies and Tools for Streamlining Inventory Management Processes

Tech and devices are critical. They smooth out inventory management. A solid software development framework allows businesses to build efficiency, accuracy, and perceivability in the supply chain. Utilizing progressed solutions can assist businesses with conquering inventory management challenges. They can likewise drive functional greatness. Here are a few critical innovations and instruments for smoothing out inventory management processes:

1. Inventory Management Software

Firstly, Inventory management software gives a focal stage. It tracks and oversees inventory continuously. A report by Market Research Future says the worldwide market for supply chain inventory software will reach USD 3.83 billion by 2025. The rising use of cloud-based solutions and the requirement for better inventory perceivability drive this development.

2. RFID (Radio-Frequency Identification) Technology

Secondly, RFID innovation empowers programmed ID. It tracks inventory of things utilizing radio transmissions. The RFID Diary’s examination demonstrates the way that RFID innovation can further develop inventory accuracy by up to almost 100%. It can likewise reduce inventory-related labor costs by 30-50%.

3. Barcode Scanning Systems

Thirdly, Barcode scanning systems permit custom software development consulting companies to catch inventory data. Companies do this utilizing standardized identification marks. Aberdeen Gathering did a review. They found that companies utilizing scanner tag filtering have 95% inventory accuracy. In correlation, companies with manual inventory have 65%.

4. IoT (Internet of Things) Sensors

IoT sensors permit ongoing observing of inventory levels, conditions, and areas. They work all through the supply chain. McKinsey and Company appraises that the IoT market for inventory management could produce up to USD 2.4 trillion by 2025.

5. Warehouse Management Systems (WMS)

Warehouse management frameworks automate and further develop warehouse tasks. They cover getting, putaway, picking, pressing, and delivery. A report by Grand View Research says the worldwide warehouse management framework market will arrive at USD 5.72 billion by 2025. The market will be driven by the requirement for better warehouse efficiency and precise inventory.

6. Predictive Analytics

Finally, Predictive analytics uses past inventory data and high level math to anticipate future interest. They likewise spot drifts and improve inventory levels. A survey by Forbes Experiences saw that 86% of businesses use prescient examination for inventory management in supply chain management. They report large enhancements in inventory turnover and customer satisfaction.

Businesses can embrace these apparatuses to smooth out inventory management. They can diminish costs, cut mistakes, and further develop supply chain execution. The right solutions are tailored to explicit business needs. They can drive competitive advantage and fuel development in the present quick evolving commercial center.

Transform Your Business with Custom Software Development. Request a Free Consultation Today!

Achieving Supply Chain Success Through Effective Inventory Management

Success in the supply chain depends on great inventory management. It is the foundation of proficient activities and resource use. Businesses that succeed in inventory management in supply chain can set aside heaps of cash. They can likewise further develop customer satisfaction and gain a competitive advantage. How about we check out the critical variables and data. They support supply chain success through great inventory management.

1. Cost Reduction

Firstly, Effective inventory management limits conveying costs related with overabundant inventory, stockpiling, and oldness. The National Retail Federation’s Inventory Accuracy and Shrinkage Study demonstrates the way that holding costs can be 25-30% of an organization’s complete inventory.

2. Improved Cash Flow

Secondly, Advancing inventory levels opens up capital. It would somehow be restricted in overabundance inventory, supporting cash flow and liquidity. A survey by the Supply Chain Management Survey found that companies with great inventory practices see a 20-half drop in conveying costs. This reduction leads to better cash flow.

3. Enhanced Customer Satisfaction

Thirdly, Accurate inventory management ensures product availability, decreasing the probability of stockouts and rainchecks. Research shows that 81% of customers will pay more for a better customer experience. Warehouse inventory management software shows the significance of inventory management in the supply chain. It is critical to meeting customer expectations.

4. Streamlined Operations

Good inventory management streamlines warehouse tasks. It likewise further develops request satisfaction and supply chain strategies. The Aberdeen Group found that companies with improved inventory processes arrive at a 95% accuracy rate. For companies with unfortunate supply chain practices, the rate is simply 65%.

5. Competitive Advantage

Such businesses succeed at inventory management. This gives them an edge by further developing efficiency, reducing expenses, and raising customer satisfaction. The Harvard Business Survey says that companies great at inventory management show improvement over their friends. They beat them by 73% in income development and 12% in profitability.

6. Resilience to Supply Chain Disruptions

Great inventory management decreases the risk of stockouts. It additionally cuts the risk of overabundance inventory and supply chain interruptions. Best software consulting companies can improve supply chain versatility by utilizing powerful inventory management. They can likewise adjust to advertise changes and disturbances.

7. Data-Driven Decision Making

In conclusion, Continuous inventory data allows businesses to pursue informed choices. They can use it to design stock recharging, creation planning, and request forecasting. A survey by Gartner found that companies with continuous inventory data can answer 20% faster to showcase request changes. This is contrasted with those with obsolete inventory frameworks.

Utilizing effective inventory management helps custom software development outsourcing companies succeed. It allows them to reduce expenses, work better, and satisfy customers. It is critical to Embrace tech. Utilizing best practices and cultivating cooperation across the supply chain is as well. This opens the maximum capacity of inventory management. It drives supply chain success.

Steps to Improve Inventory Management Practices in Supply Chain

Great inventory management is significant in the supply chain. It enhances activities, cut costs, and lifts customer satisfaction. However, many inventory management software for small businesses battle to deal with their inventory well. This leads to issues like stockouts, overabundance inventory, and higher conveying costs. To address these difficulties and further develop supply chain execution, we should use procedures. They will further develop inventory management. This guide frames key stages. Businesses can use them to further develop their inventory management and be more proficient.

1. Conduct a Comprehensive Inventory Audit

Firstly, by doing a careful inventory review. This will evaluate current inventory levels, accuracy, and association. The National Retail Federation says inventory errors can cost up to 2% of deals.

2. Implement Demand Forecasting

Secondly, Use past deals data, market patterns, and customer experiences. Use them to gauge future interest well. Forecasting assists businesses with expecting customer interest. Emergency clinic inventory management software allows them to change inventory likewise. This lessens the risk of stockouts and abundance inventory.

3. Optimize Reorder Points and Order Quantities

Thirdly, Find the best reorder focuses and request sizes. Base them on request gauges, lead times, and administration level objectives. Utilizing methods like Economic Order Quantity (EOQ) analysis can help. They cut inventory holding costs while guaranteeing sufficient inventory.

4. Embrace Just-in-Time (JIT) Inventory Management

Take on JIT inventory management principles. They cut inventory holding costs and lift cash flow. JIT inventory management adjusts creation and inventory levels with customer interest. This cuts the abundance of inventory and waste.

5. Leverage Technology Solutions

Put resources into inventory management software. Additionally, put resources into innovations like RFID, standardized tag checking, and IoT sensors. They will further develop inventory perceivability and control. The RFID Diary says RFID innovation can further develop inventory accuracy by up to close to 100%. It can likewise reduce inventory work expenses by 30-50%.

6. Streamline Warehouse Operations

Carry out proficient warehouse management practices to upgrade inventory capacity, association, and recovery. Smoothing out warehouse tasks speeds up request satisfaction. Agile software development life cycle likewise cuts picking mistakes and lifts supply chain efficiency.

7. Establish Supplier Collaboration

Work with providers to cut lead times. Guarantee conveyances are on time and further develop supply chain dependability. A concentrate by the University of Tennessee found that utilizing seller oversaw inventory (VMI) can cut inventory by 20-30%. It can likewise support inventory turns by 5-10%.

8. Check Key Performance Indicators (KPIs)

Track and watch key inventory KPIs. These incorporate inventory turnover proportion, fill rate, and stockout rate. Examining KPIs helps track down issues. It likewise gauges the effectiveness of inventory enhancements.

9. Continuous Improvement

Make a culture of progress. Do this by inspecting and further developing inventory processes. Support input from partners. Use best practices and remain refreshed on industry patterns and tech.

10. Invest in Employee Training and Development

Lastly, Give exhaustive training and development projects to representatives associated with inventory management. Representatives with great training can deal with inventory well. This cuts blunders and lifts the entire supply chain.

By following these means, custom software development consulting companies can further develop their inventory management. This will reduce expenses and make activities more proficient all through the supply chain. By watching execution and utilizing innovation, businesses can deal with their inventory. They should do so constantly, however, it can likewise make more noteworthy progress by cultivating coordinated effort.

Transform Your Software Vision into Reality – Book A 30 Minutes Free Consultation!

Consultation and Implementation Services for Enhanced Inventory Management in Supply Chain

Businesses need to further develop their inventory management in supply chain. Consultation and implementation services offer master help. They are important. These services are for the particular necessities and difficulties of businesses. They assist with overseeing inventory well, driving efficiency, cost investment funds, and customer satisfaction. Consultation services start with a full evaluation. This checks the ongoing inventory processes. It incorporates a review of inventory levels, accuracy, and design. Data from the National Retail Federation demonstrates the way that inventory blunders can lead to a deficiency of up to 2% of yearly deals. This highlights the need to resolve these issues.

When the appraisal is finished, experts work with custom enterprise software development. They foster custom systems and solutions for better inventory management. This might incorporate utilizing demand forecasting. It likewise implies enhancing reorder focuses and request sizes. It additionally implies utilizing tech like inventory software and RFID. As indicated by the RFID Diary, RFID tech can support inventory accuracy by up to almost 100%. However, it can likewise reduce inventory work expenses by 30-half. Implementation services center around doing these procedures effectively. This incorporates making sure they fit with existing frameworks and cycles. The services additionally incorporate giving training and backing to workers.

All through the consultation and implementation process, we center around constant improvement. We track Key Performance Indicators (KPIs). They measure how well inventory management drives work. Businesses can collaborate with experienced specialists and specialist organizations. They can get the ability and resources they need. These will assist them with further developing their inventory management and drive supply chain success. With better inventory perceivability, accuracy, and control, businesses can reduce expenses. They can likewise lessen stockouts and further develop efficiency. This will give them a competitive advantage in the present high speed commercial center.

| [[Infographic Content]] |

Conclusion

Inventory management is vital to supply chain success. Its job and significance are exceptionally enormous. Good inventory management is vital to further developing efficiency. It reduces expenses and lifts customer satisfaction. By keeping the right inventory levels, hospital inventory management software can guarantee orders are occupied on time. They can likewise cut stockouts and the risk of excess inventory costs. Likewise, utilizing progressed inventory tech and procedures does this. They give businesses better sight and command over their inventory. This assists them with making better decisions and enduring market fluctuations. Eventually, businesses that emphasize on and put resources into great inventory management prevail in supply chains. Along these lines, they are better situated to do as such. They likewise gain a competitive advantage in the present quick impacting business world.

Frequently Asked Questions about Inventory Management in Supply Chain

1. What is Inventory Management, and Why is it Important in the Supply Chain?

Inventory management in supply chain includes supervising the flow of merchandise all through a business’ inventory. Critical in the supply chain, it guarantees that the perfect items are available at the ideal general setting, eliminating stockouts and overabundant inventory while likewise helping functional efficiency.

2. What are The Common Challenges Businesses Face in Inventory Management?

Inventory management has normal difficulties. These incorporate mistaken request forecasting. This can cause stock outs or overabundance inventory. Additionally, terrible warehouse management might cause disrupted inventory. It can likewise lead to higher conveying costs. The difficulties are exacerbated by an absence of perceivability into inventory levels and development. Accordingly, this need makes it difficult for businesses to choose and answer changes sought after like the agile software development life cycle. Finally, manual data passage and old inventory following can lead to mistakes.

3. How can Businesses Improve Inventory Accuracy and Visibility?

Businesses can further develop inventory accuracy and perceivability. They can do this by utilizing progressed inventory tech. This tech incorporates RFID, standardized tag scanners, and inventory software. These solutions give constant experiences into inventory levels, areas, and developments.

4. What are Some Best Practices for Optimizing Inventory Levels?

Best practices incorporate utilizing request forecasting. Additionally, improving reorder focuses and request amounts, embracing in the nick of time inventory management principles, and involving innovation for inventory following and control.

5. How can Businesses Measure The Effectiveness of Their Inventory Management Practices?

Businesses can quantify effectiveness utilizing key execution markers (KPIs). These incorporate inventory turnover proportion, fill rate, stockout rate, and conveying costs. Observing these KPIs assists businesses with tracking down regions to get to the next level. However, it additionally allows them to check the success of their inventory drives.